Using compressed air, these machines create a flurry of soda that is propelled toward the surface to be treated. Read More…

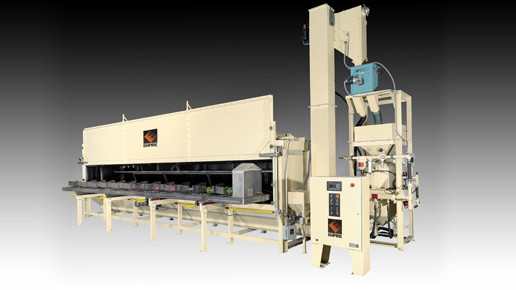

Our sandblast equipment is designed to handle a wide variety of applications and we use manufacturing methods that guarantee these machines will stand the test of time.

We have decades of experience in the finishing industry and we specialize in aqueous washing, abrasive blasting, vibratory finishing, polishing and buffing.

With over 100 years of combined dust-collecting experience, Rapid Prep LLC is a leader in the dust-collecting and sandblast equipment industry. We offer a wide range of products to meet the needs of our customers, with customization options available. Our team is dedicated to advancing our company and raising industry standards.

Cardinal Parts & Equipment LLC specializes in designing high-quality abrasive blasting equipment. The equipment they offer includes tumble blast equipment, rim blast equipment, dust collectors, and hanger blast equipment. They also sell abrasives like steel shot, stainless steel shot, and cast zinc shot. Their services include service calls, inspections, financing, and equipment rebuilding....

More Soda Blasting Equipment Manufacturers

The resulting pressurized stream can be adjusted to accomplish a variety of tasks such as removing coatings, roughening smooth surfaces, smoothing rough surfaces, etching, carving, degreasing, deburring, peening, deflashing and descaling equipment and parts made of metal, wood, plastic and glass.

An increasingly popular alternative to harsher blasting media, soda blasters can be used on both industrial and delicate components ranging from ship hulls to printed circuit boards. The versatility of these machines allow their use in a number of industries including the automotive, shipbuilding, construction, agriculture, industrial cleaning and processing, aerospace, decorative design, woodworking and glass industries.

In addition to ships and circuit boards, soda blasting is used to resurface and clean large and small elements including nuts, bolts, decorative glass, engine components, bridges, aircraft, heat exchangers and building components. Soda blasting has many benefits over traditional sandblasting including reduced heat waste and significantly reduced risk of substrate pitting.

Similar in design to bead blasters, soda blasting machines all have the same basic elements. An air compressor is connected to a power source as well as a hopper or vessel containing the abrasive soda bicarbonate. Although this material is actually of a white crystalline structure, it is used in a powdered form for blasting.

Hoses of varying length connect the hopper to a gun-like nozzle. Pulling a trigger or pressing a switch pushes or pulls air through the closed system creating a vacuum which pulls the abrasive grit through the tubing and out of the nozzle in a high pressure stream directed towards the substrate to be cleaned or resurfaced. Though this is a general explanation, specific machines will vary and should be considered in relation to the intended goals of the process.

The material of the substrate should be carefully considered with regards to flow rate and blast pressure to ensure it is not damaged by the abrasive process. As sodium bicarbonate is not a very abrasive substance, damage is unlikely. This substance, more commonly known as baking soda, is extremely friable and undergoes micro fragmentation on impact resulting in minimal byproduct production. Additionally, soda blasting is FDA approved as the substance is non-toxic, non-flammable, non-hazardous and water-soluble, making it an environmentally safe option.

Deburring Machinery

Deburring Machinery Industrial Parts Washers

Industrial Parts Washers Sandblast Equipment

Sandblast Equipment Ultrasonic Cleaners

Ultrasonic Cleaners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services