A shot blasting machine is a means of abrasive blast cleaning by forcibly propelling a stream of abrasive material under high pressure. The purpose of the process is to smooth, shape, and remove paint, rust, contaminants, and coatings. To complete certain manufacturing processes, the surfaces of completed or in process parts have to be cleaned of debris, which cannot be removed by solvents, water, or chemicals. Such cleanings require the mechanical process of shot blasting. Read More…

Our sandblast equipment is designed to handle a wide variety of applications and we use manufacturing methods that guarantee these machines will stand the test of time.

We have decades of experience in the finishing industry and we specialize in aqueous washing, abrasive blasting, vibratory finishing, polishing and buffing.

With over 100 years of combined dust-collecting experience, Rapid Prep LLC is a leader in the dust-collecting and sandblast equipment industry. We offer a wide range of products to meet the needs of our customers, with customization options available. Our team is dedicated to advancing our company and raising industry standards.

Cardinal Parts & Equipment LLC specializes in designing high-quality abrasive blasting equipment. The equipment they offer includes tumble blast equipment, rim blast equipment, dust collectors, and hanger blast equipment. They also sell abrasives like steel shot, stainless steel shot, and cast zinc shot. Their services include service calls, inspections, financing, and equipment rebuilding....

More Shot Blasting Machine Manufacturers

Types Of Conditions That Require Shot Blasting Machine

The types of conditions that require a shot blasting machine can be parts that are heavily coated in rust, which cannot be removed by scraping or high pressure water. Steel surfaces that are uneven or contain burrs can be more efficiently cleaned using shot blasting. The process of shot blasting is ideal for cleaning metal surfaces that have been exposed to rust or corrosion.

What is the Shot Blasting Machine Process?

Shot blasting machines are described using a variety of terms, which include peening, grit blasting, media blasting, and abrasive blasting. Regardless of the term being used to describe the process, all shot blasting methods follow the same basic principle of using some form of abrasive material to remove unwanted matter from a metal or concrete surface.

Though shot blasting may be compared to sandblasting, the process and method of completing shot blasting is different in its execution and effectiveness. Shot blasting uses high velocity to propel pellets or beads made of steel, copper, or aluminum as an abrasive material. The force and speed of the beads are concentrated by the shot blasting machine against the surface to be cleaned.

The force behind a shot blasting is created by a centrifugal wheel that is powered by a motor, which produces kinetic force to shoot and propel the beads. The efficiency of the process comes from the centrifugal wheel that requires a limited amount of power. Regardless of the lack of power, shot blasting is a thorough, aggressive, economical, and efficient method for preparing and cleaning surfaces.

Types of Shot Blasting

There are different types of shot blasting machines designed to clean a wide array of surfaces as well as metal parts. The variation in blasting machines depends on whether the machine is mobile or chambered, is part of an assembly process, similar to a vacuum for surface cleaning of floors, and other factors that have been designed to meet a specific need.

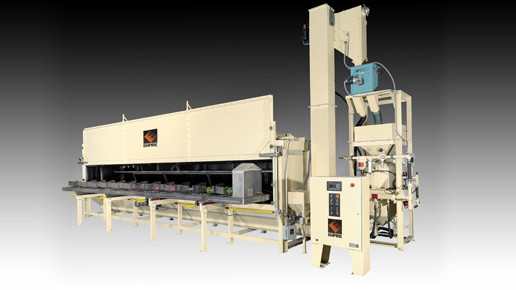

The tumble type of blasting machine is a chamber style where parts are loaded into a tumbler chamber where abrasive is sprayed at components and parts. It is a method used for hard to clean parts that need to be deburred, cleaned, and descaled. The conveyor method of shot blasting is an automated solution to cleaning many parts efficiently as part of a production process. Parts are loaded onto rollers of a conveying system and pass through an enclosed shot blasting chamber. Inside the chamber, parts are blasted by four parallel blasters.

Portable shot blasting equipment offers versatility and flexibility. In cases where a floor or other surface has to be cleaned, roughened, or have metal particles removed, portable shot blasting equipment is used since it is mobile enough to be moved to a variety of locations.

Benefits of Shot Blasting Machines

Proper surface preparation is an essential part of many manufacturing, cleaning, and production operations. The removal of imperfections, smoothing of surfaces, and adding texture helps to prepare parts, components, and surfaces for further processing. Each of these processes can be completed by hand, but shot blasting offers a more efficient and labor-saving method.

Shot blasting is quick and effective. In all production operations, efficiency is the key to success. Though manual labor can prepare surfaces, it takes too long and costs too much. Shot blasting is significantly faster and exceptionally more efficient as well as productive.

A major concern for business is using methods that are cost effective. Shot blasting machines eliminate and significantly lower labor costs as well as reduce processing time. The abrasives, grit, and beads used in shot blasting equipment is inexpensive and power saving.

All businesses and production operations are focusing on their environmental footprint, which has become a universal concern. Shot blasting uses centrifugal force that requires little energy to complete its function. There isn’t any need for water, compressed air, or other means of creating force, making shot blasting very eco-friendly.

Deburring Machinery

Deburring Machinery Industrial Parts Washers

Industrial Parts Washers Sandblast Equipment

Sandblast Equipment Ultrasonic Cleaners

Ultrasonic Cleaners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services