Blast cabinets are an essential piece of equipment for various industries, from automotive to aerospace, manufacturing to restoration. They are designed to clean or finish parts by blasting them with abrasive media such as sand, glass beads, or walnut shells. In this article, we will provide an in-depth look into blast cabinets, including their components, design and material variations, benefits, and applications. Read More…

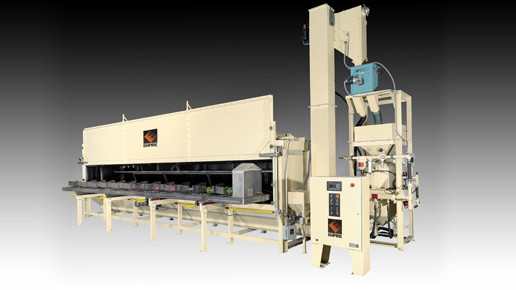

Our sandblast equipment is designed to handle a wide variety of applications and we use manufacturing methods that guarantee these machines will stand the test of time.

We have decades of experience in the finishing industry and we specialize in aqueous washing, abrasive blasting, vibratory finishing, polishing and buffing.

With over 100 years of combined dust-collecting experience, Rapid Prep LLC is a leader in the dust-collecting and sandblast equipment industry. We offer a wide range of products to meet the needs of our customers, with customization options available. Our team is dedicated to advancing our company and raising industry standards.

Cardinal Parts & Equipment LLC specializes in designing high-quality abrasive blasting equipment. The equipment they offer includes tumble blast equipment, rim blast equipment, dust collectors, and hanger blast equipment. They also sell abrasives like steel shot, stainless steel shot, and cast zinc shot. Their services include service calls, inspections, financing, and equipment rebuilding....

More Blast Cabinet Manufacturers

Components of Blast Cabinets

All blast cabinets share the same components, including the enclosure, blasting gun, abrasive media, abrasive delivery system, dust collector, and air compressor. These components are each explained below in greater detail.

Enclosure

The enclosure is the main structure of the blast cabinet that houses all the other components. It is typically made of steel, aluminum, or other durable materials to withstand the abrasive blasting process. The enclosure may have doors, windows, and a viewing screen to allow the operator to see the workpiece during blasting.

Blast Gun

The blast gun is the handheld tool used to direct the abrasive media onto the workpiece. It is connected to the abrasive delivery system and is typically made of steel or other durable materials. The blast gun has a nozzle that controls the size and velocity of the abrasive media stream.

Abrasive Media

The abrasive media is the material used to blast the workpiece. It can be made of sand, glass beads, aluminum oxide, or other materials depending on the desired surface finish and the type of material being blasted.

Abrasive Delivery System

The abrasive delivery system delivers the abrasive media to the blast gun for blasting. It consists of an air compressor, hoses, valves, and a pressure regulator. The compressor pumps air into the abrasive storage tank, which forces the abrasive media through the delivery hose and into the blast gun.

Dust Collector

The dust collector is an essential component of a blast cabinet as it removes dust and debris generated during the blasting process. It helps to maintain a clean and safe work environment and prevent respiratory health issues. The dust collector consists of a fan, filter, and collection bin.

Air Compressor

The air compressor provides the compressed air necessary to power the abrasive delivery system and the blast gun. The compressor can be electric or gas-powered and must have the capacity to supply enough air pressure and volume to meet the demands of the blast cabinet.

Design and Material Variations

There are three main types of blast cabinets: siphon blast cabinets, pressure blast cabinets, and wet blast cabinets. Siphon blast cabinets use a siphoning system to draw the blasting media into the blasting gun, while pressure blast cabinets use compressed air to force the media through the blasting gun. Wet blast cabinets use a mixture of water and abrasive media for cleaning or finishing parts, reducing the amount of dust generated.

Blast cabinets can also be made from different materials such as steel, aluminum, or polyethylene. Steel is the most common material used for blast cabinets as it is durable and can withstand high pressures. Aluminum is a lightweight option that is also corrosion-resistant. Polyethylene is a cheaper alternative that is suitable for light-duty applications.

Considerations Regarding Blast Cabinets

While blast cabinets are incredibly useful, there are potential considerations to keep in mind. Safety precautions must be taken, such as wearing ear and eye protection and ensuring proper ventilation in the workspace. Additionally, contaminated media must be disposed of properly to avoid environmental pollution.

Benefits of Blast Cabinets

Despite the potential negative considerations, blast cabinets offer several benefits. They increase efficiency and reduce manual labor, resulting in consistent results. Blast cabinets can also be customized to suit specific applications and can be used for both small and large parts.

Applications of Blast Cabinets

Blast cabinets have numerous applications, making them an essential tool for many industries, including:

Automotive Industry

In the automotive industry, blast cabinets are commonly used for cleaning engine components such as cylinder heads, pistons, and engine blocks. They can also be used for removing rust and paint from metal car bodies, preparing the surface for repainting. Additionally, they are useful for cleaning and repairing old parts such as carburetors, brake calipers, and radiators.

Aerospace Industry

In the aerospace industry, blast cabinets are used for removing paint and corrosion from aircraft parts. They are also useful for cleaning landing gear, engine components, and hydraulic systems. The aviation industry requires high-quality finishes on their products, and blast cabinets provide consistent results.

Manufacturing Industry

Blast cabinets are used in the manufacturing industry for deburring and descaling metal parts, creating a smooth surface. They can also be used for removing paint or coatings from parts before assembly. Blast cabinets are also used for cleaning molds in the plastic injection molding process to remove buildup.

Restoration Industry

Blast cabinets are a valuable tool in the restoration industry for restoring old furniture, machinery, and vehicles. They are used for stripping old paint, rust, and corrosion from surfaces, preparing them for repair and refinishing. Blast cabinets can be used to restore vintage bicycles, motorcycles, and cars.

DIY Projects

Blast cabinets are becoming increasingly popular among DIY enthusiasts for personal projects such as restoring old cars, motorcycles, and bicycles. They are also useful for creating custom finishes on metal or wood surfaces, including jewelry, home decor, and small machinery.

Marine Industry

In the marine industry, blast cabinets are used for removing rust and paint from boats, ships, and marine equipment. They are also useful for cleaning and maintaining propellers and other metal components. Blast cabinets can help extend the lifespan of marine equipment and keep boats looking new.

Medical Industry

In the medical industry, blast cabinets are used for cleaning and sterilizing surgical instruments. They are also useful for cleaning implants before surgery. Blast cabinets are an essential tool for maintaining a sterile environment in the medical industry.

Construction Industry

In the construction industry, blast cabinets are used for cleaning concrete surfaces and preparing them for coatings or repairs. They are also useful for removing paint and rust from steel structures.

Choosing the Correct Blast Cabinet Manufacturer

To ensure you have the most productive outcome when purchasing a blast cabinet from a blast cabinet manufacturer, it is important to compare several companies using our directory of blast cabinet manufacturers. Each blast cabinet manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or to request a quote. Review each blast cabinet business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple blast cabinet companies with the same form.

Deburring Machinery

Deburring Machinery Industrial Parts Washers

Industrial Parts Washers Sandblast Equipment

Sandblast Equipment Ultrasonic Cleaners

Ultrasonic Cleaners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services