This force helps to remove contaminants from the surface and smooth out bumps to improve the overall durability and strength of the metal, as well as the appearance. Read More…

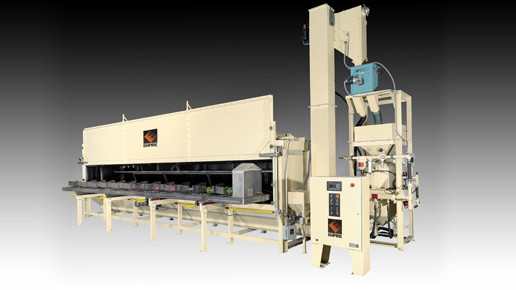

Our sandblast equipment is designed to handle a wide variety of applications and we use manufacturing methods that guarantee these machines will stand the test of time.

We have decades of experience in the finishing industry and we specialize in aqueous washing, abrasive blasting, vibratory finishing, polishing and buffing.

With over 100 years of combined dust-collecting experience, Rapid Prep LLC is a leader in the dust-collecting and sandblast equipment industry. We offer a wide range of products to meet the needs of our customers, with customization options available. Our team is dedicated to advancing our company and raising industry standards.

Cardinal Parts & Equipment LLC specializes in designing high-quality abrasive blasting equipment. The equipment they offer includes tumble blast equipment, rim blast equipment, dust collectors, and hanger blast equipment. They also sell abrasives like steel shot, stainless steel shot, and cast zinc shot. Their services include service calls, inspections, financing, and equipment rebuilding....

More Blasting Machine Manufacturers

Sand blasting is the most commonly used type of blasting, but there are several other ways that abrasive blasting can be done. Some shops offer blasting as a service to industrial customers, while other manufacturers sell blasting machines directly to companies in restoration or repair industries.

For sand blasting, a high pressure air blast system shoots sand through a nozzle that is pointed at the part being cleaned. The force of the sand hitting the metal causes abrasion that smoothes the surface out. Sand blasting is used on vehicle restoration projects to treat car parts that have been taken apart before they are coated with fresh paint. It is much easier to paint a surface correctly if it has been treated using a blasting machine.

Sometimes this is the only way to restore the car to its original appearance. There are other types of blasting machines that use different methods but essentially accomplish the same thing. These are all generally good for surface finishing applications, but some may be optimal for use in particular industries and situations. Hydro-blasting, for example, uses highly pressurized water to blast surfaces like the exterior walls of buildings.

A dry-ice blasting machine uses air and dry-ice under pressure that are ejected from a nozzle. This effectively removes surface contaminants due to of the force of the carbon dioxide.

Blasting machines can be made for portable or stationary use. Portable systems are usually powered by a diesel-fueled air compressor. The compressor fills a blast pot with pressurized air. This pot is where the air interacts with the abrasive materials and then travels through a hose to the nozzle where it is ejected.

A blast cabinet is a stationary blasting machine where parts are placed in a sealed enclosure. A foot pedal turns the blaster on and off, and the operator can see the object through a small window and move it by inserting his or her hands into rubber gloves that are integrated into the side of the machine.

Deburring Machinery

Deburring Machinery Industrial Parts Washers

Industrial Parts Washers Sandblast Equipment

Sandblast Equipment Ultrasonic Cleaners

Ultrasonic Cleaners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services