Sandblasting, also known as abrasive blasting, is a surface finishing technique where abrasive particles are sprayed against a surface at high pressure using a powered machine, often an air compressor and a sandblasting machine. Since sand particles are used to blast the surface, it is known as “sandblasting”. Technically speaking, the word “sandblaster” should refer only to a media blasting machine that makes use of silica particles, but the designation is used to describe any media blaster, regardless of its blasting media. Read More…

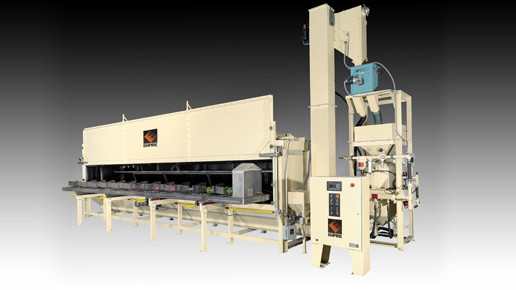

Our sandblast equipment is designed to handle a wide variety of applications and we use manufacturing methods that guarantee these machines will stand the test of time.

We have decades of experience in the finishing industry and we specialize in aqueous washing, abrasive blasting, vibratory finishing, polishing and buffing.

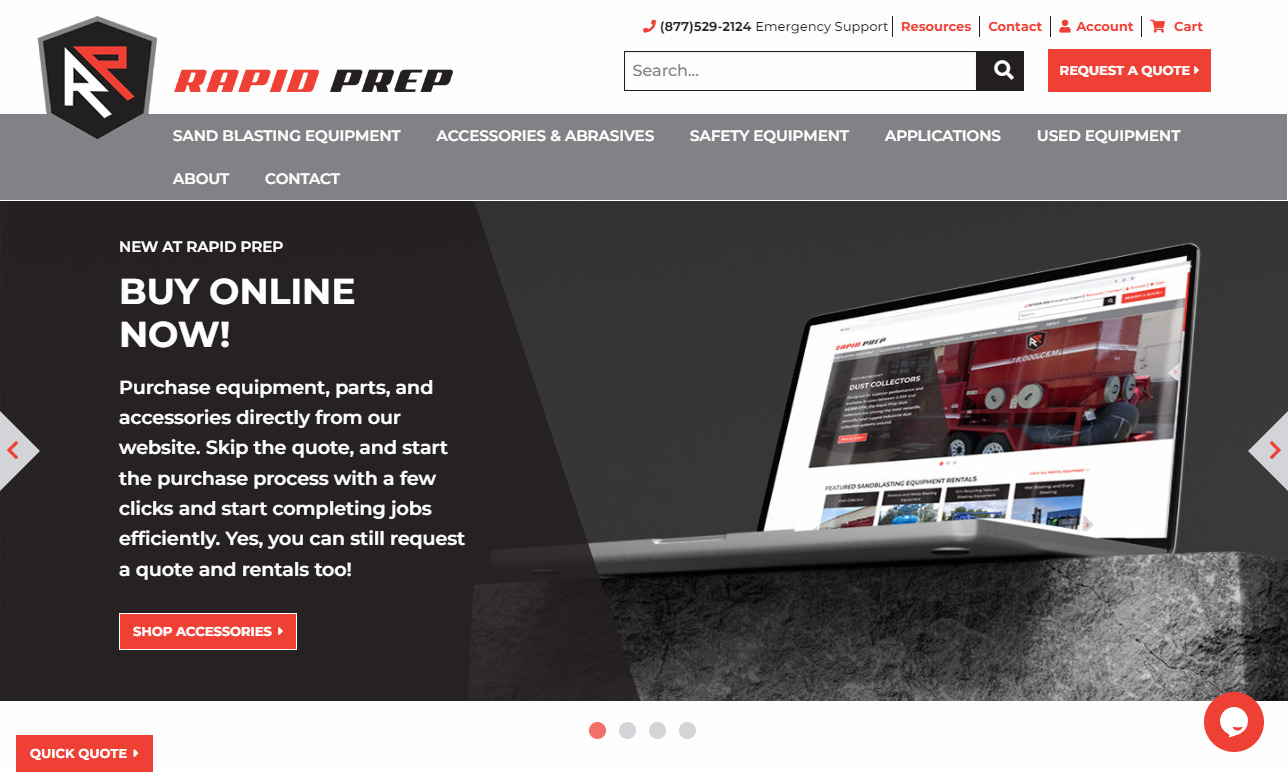

With over 100 years of combined dust-collecting experience, Rapid Prep LLC is a leader in the dust-collecting and sandblast equipment industry. We offer a wide range of products to meet the needs of our customers, with customization options available. Our team is dedicated to advancing our company and raising industry standards.

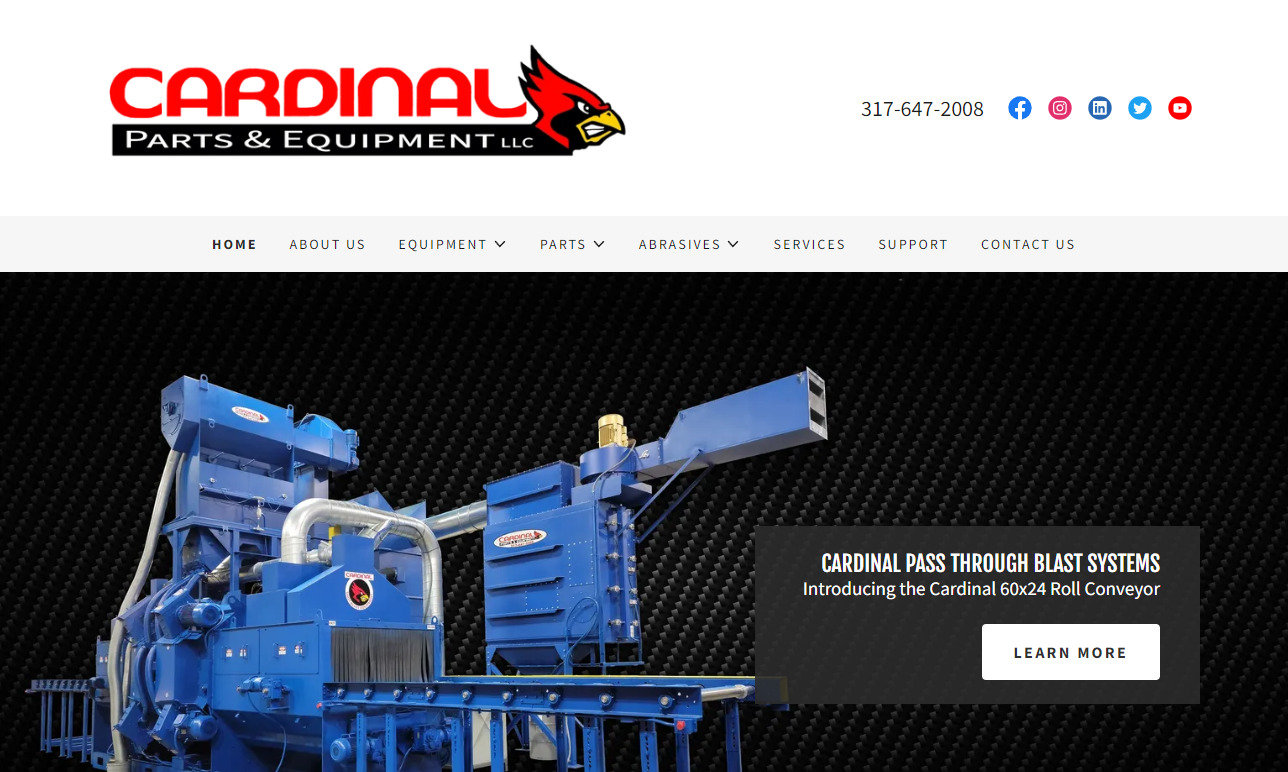

Cardinal Parts & Equipment LLC specializes in designing high-quality abrasive blasting equipment. The equipment they offer includes tumble blast equipment, rim blast equipment, dust collectors, and hanger blast equipment. They also sell abrasives like steel shot, stainless steel shot, and cast zinc shot. Their services include service calls, inspections, financing, and equipment rebuilding....

More Sandblaster Manufacturers

The texture of the surface becomes smoother and more uniform when the sand particles impact it. Sandblasting makes use of the abrasive qualities of sand to produce surfaces that are smoother and have fewer physical faults. It goes without saying that sand is abrasive and coarse.

These characteristics allow it to remove extra or undesired material from a surface by wearing it away. For instance, sandpaper has a large number of tiny sand particles in it. The sand smooths out the roughness of a surface by scraping away some of the top-layer material. The only difference between sandblasting and that process is the use of highly pressured sand.

How Sandblasters Work

Pouring the sand into the sandblasting machine is the initial stage in sandblasting. Sandblasting machines have a chamber on top in which the sand is deposited. When the air compressor is turned on, it connects to the sandblasting machine and releases the sand through a handheld nozzle.

Sand pressure can range from 50 to 130 pounds per square inch depending on the parameters (PSI). The surface is subsequently "blasted" with sand, which thanks to its abrasive qualities can produce a smoother finish. For instance, concrete is frequently sandblasted. The concrete is treated with sandblasting after it has been poured and given time to dry. The procedure smoothes out the concrete by removing some of the extra material.

Types of Sandblasters

The different types of sandblasters include:

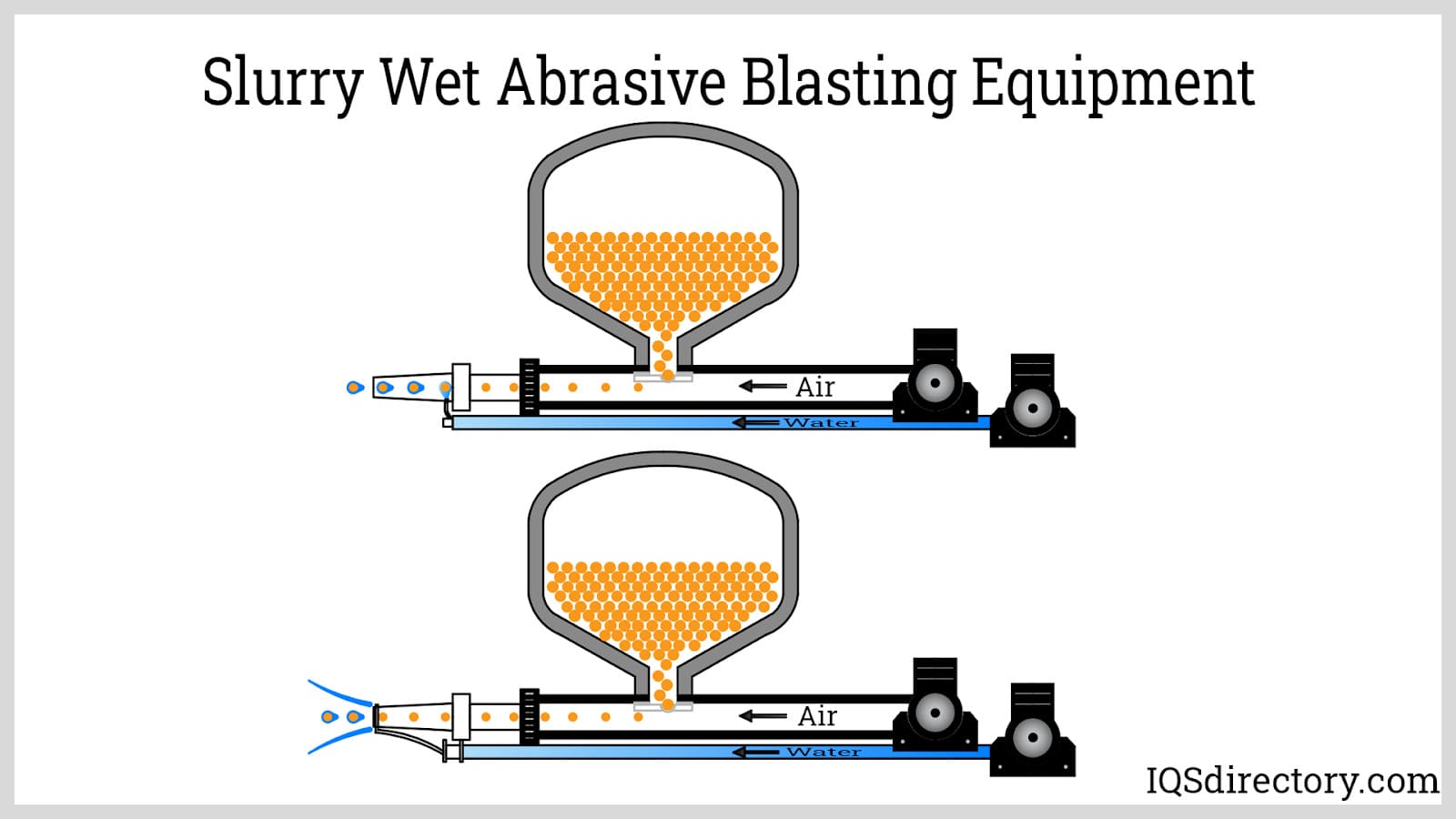

Slurry Blasting Equipment

It is possible to convert dry blasting equipment to offer wet blasting. Air abrasive water blasters are another name for slurry blast devices. An air blasting pistol is equipped with a water injection nozzle or water ring (halo), which adds water to the blast media stream. They reduce the amount of dust produced by 50% to 85%. Less effective in controlling dust than water induction or injection nozzles are the water ring or halo nozzles.

Slurry blasters offer a great degree of versatility because they can dry blast, wet blast, rinse, and dry parts. Cleaning up the muddy mess left behind by slurry blasters in field applications is one disadvantage. The hefty water hose that is coupled to the slurry blast equipment makes it difficult for the operator to carry and manage.

Abrasive Blasters

The traditional sandblasters known as "abrasive blasters" are made to strike a surface with sharp, hard grains. Aluminum oxide, silicon carbide, coal slag, garnet, mineral sands, olivine, pumice, staurolite, broken glass, abrasive sponge media, micro-abrasives, and copper slag are some examples of the compositions used in blasting abrasives. Abrasive blasters' blast nozzles, blast hoses, and surfaces need to be more wear-resistant and need to be maintained and replaced more frequently.

Non Abrasive Blasters

Walnut shells, soda (sodium bicarbonate or baking soda), plastic grit, maize cobs, and starch are examples of non-abrasive media. Abrasive blasters do not require components with the extraordinary wear resistance of equipment built for blasting non-abrasive media. Internal surfaces, blast nozzles, and blast hoses should last longer before needing to be replaced.

Applications of Sandblasters

- A professional sandblaster can use media blasting equipment for a variety of tasks, but the method by which they complete these tasks is always the same: compressed air or water propels small, abrasive materials toward a surface in order to alter its properties. This is one of the few concepts that all media blasters share. To meet the various demands for media blasting services, media blasters come in a wide variety of sizes and configurations.

- An automated blasting system may be efficient for businesses that provide blasting services for small parts on a big scale since it can enable a continuous treatment stream with a minimum of technical monitoring. A blasting cabinet may be a better option for businesses that provide meticulous, customized blasting of particular things since it gives professionals the most control over the procedure while reducing the risk of bodily damage.

- For blasting specialists to provide their services to clients whose property has been vandalized, is at risk of corrosion, or needs maintenance like painting or finishing, portable media blasters are essential.

Choosing the Right Sandblaster Manufacturer

To make sure you have the most productive outcome when purchasing sandblasters from sandblaster manufacturers, it is important to compare at least 4 to 5 companies using our sandblaster directory. Each sandblaster manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each sandblaster company using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple sandblaster companies with the same quote.

Deburring Machinery

Deburring Machinery Industrial Parts Washers

Industrial Parts Washers Sandblast Equipment

Sandblast Equipment Ultrasonic Cleaners

Ultrasonic Cleaners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services