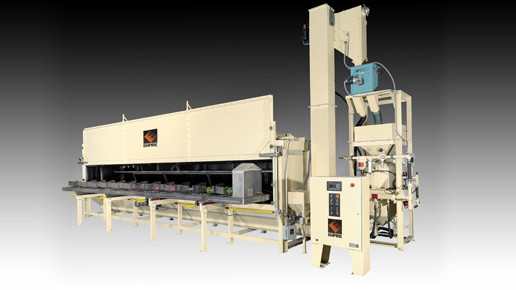

Sandblast equipment, also known as sandblasting equipment, is a versatile tool widely used in various industries for surface preparation, cleaning, and finishing purposes. The equipment typically consists of a blasting cabinet or chamber, an air compressor, a blasting gun or nozzle, and an abrasive material like sand or other media. The process involves propelling the abrasive material at high speed against a surface, effectively removing contaminants, old coatings, rust, or impurities, and creating a smooth and clean surface. Read More…

Our sandblast equipment is designed to handle a wide variety of applications and we use manufacturing methods that guarantee these machines will stand the test of time.

We have decades of experience in the finishing industry and we specialize in aqueous washing, abrasive blasting, vibratory finishing, polishing and buffing.

With over 100 years of combined dust-collecting experience, Rapid Prep LLC is a leader in the dust-collecting and sandblast equipment industry. We offer a wide range of products to meet the needs of our customers, with customization options available. Our team is dedicated to advancing our company and raising industry standards.

Cardinal Parts & Equipment LLC specializes in designing high-quality abrasive blasting equipment. The equipment they offer includes tumble blast equipment, rim blast equipment, dust collectors, and hanger blast equipment. They also sell abrasives like steel shot, stainless steel shot, and cast zinc shot. Their services include service calls, inspections, financing, and equipment rebuilding....

More Sandblast Equipment Manufacturers

The general applications of sandblast equipment include preparing surfaces for painting or coating in manufacturing and automotive industries, as well as cleaning and restoring monuments, buildings, and metal structures. We also use it to refurbish old machinery and equipment, remove graffiti, and shape materials like glass and stone in artistic endeavors. The versatility and effectiveness of sandblast equipment make it an essential tool for a wide range of industrial and surface treatment processes.

Types of Sandblast Equipment

Sandblast equipment includes a variety of tools designed to meet different industrial and surface treatment needs. Pressure blasters, using compressed air to propel abrasive material through a blasting nozzle, are ideal for heavy-duty tasks such as removing tough coatings, rust, and corrosion from metal and concrete surfaces. Siphon blasters, with their suction system to draw abrasive material into the blasting gun, offer versatility and ease of use for tasks like rust removal, surface finishing on wood and fiberglass, and general cleaning applications.

Gravity-fed blasters harness gravity to channel abrasive material into the airstream, making them ideal for precision work and intricate surface etching. This design provides enhanced control over the abrasive flow, making them popular for artistic applications and detailed surface treatments.

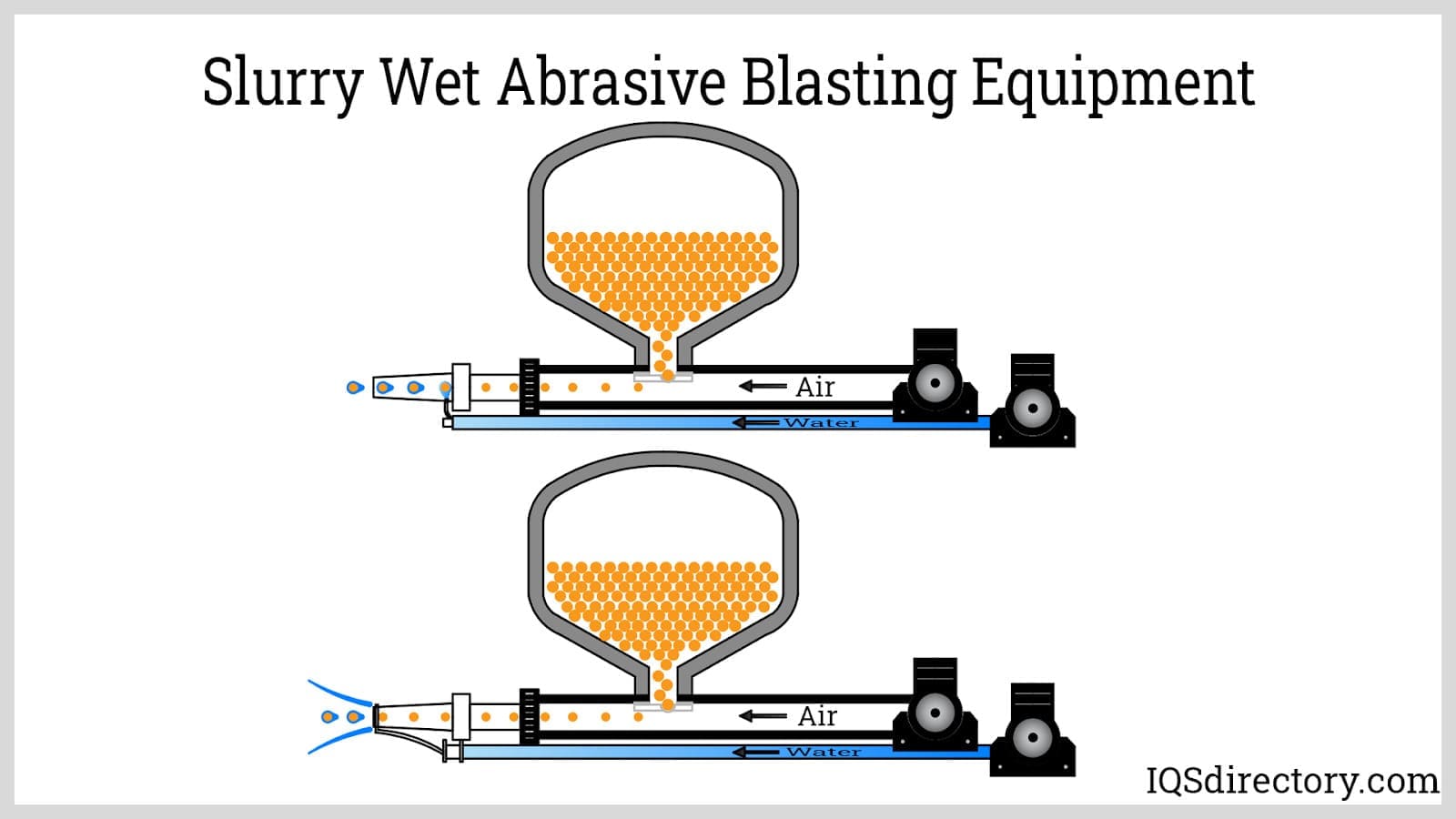

Wet blasters, also known as dustless or slurry blasters, mix water with abrasive material before applying it to a surface. This innovative approach minimizes dust, making the process more eco-friendly and enabling safer, gentler surface treatments. We often use wet blasters for tasks such as removing graffiti, cleaning sensitive surfaces like brick, stone, and wood, and restoring historic buildings.

Finally, portable dusters, also known as air dusters or air erasers, are compact handheld sandblasting tools. They are specifically crafted for precise and delicate tasks, perfect for intricate detailing or fine etching. Their lightweight and user-friendly design make them indispensable for applications in arts, crafts, and restoration work.

Each type of sandblasting equipment offers unique benefits, making them ideal for specific tasks. Pressure blasters excel in heavy-duty projects, siphon blasters provide versatility, gravity-fed blasters offer precision, wet blasters ensure dust control, and portable dusters are perfect for intricate work. Choosing the right sandblasting equipment depends on the project’s nature, the materials involved, and the desired outcome. This flexibility allows industries to tailor their equipment choices to meet their unique needs for surface preparation, cleaning, and finishing.

Choosing the Right Sandblast Equipment

Selecting the ideal sandblast equipment for a particular application is a methodical process to ensure optimal results and efficiency. We start by determining the purpose of the equipment—whether it’s for heavy-duty surface preparation, detailed etching, cleaning delicate surfaces, or removing graffiti. Next, we evaluate the material and size of the surface to be treated, which helps us choose equipment with the right capacity and efficiency. It’s crucial to ensure that the equipment is compatible with the abrasive material appropriate for the application, as different types of sandblast equipment are better suited for specific abrasive media such as sand, garnet, aluminum oxide, or baking soda. Finally, we assess the desired finish and level of precision required; gravity-fed blasters or portable dusters are ideal for intricate work, while pressure blasters or wet blasters are more effective for heavy material removal.

Environmental considerations are crucial; wet blasters are perfect for tasks needing dust control, as they minimize airborne particles and slurry waste. When planning, account for the equipment’s portability and any workspace constraints; smaller-sized blasters or portable dusters may be necessary to access tight or remote spaces. Additionally, budget and maintenance costs should be factored in; while some equipment might have higher initial costs, they could offer better efficiency and lower maintenance expenses over time. Safety and user experience are paramount; ensure the chosen equipment complies with safety standards and features an ergonomic design for user comfort during extended use.

For added assurance, let’s seek advice from industry experts or equipment suppliers and conduct small-scale tests with different equipment to assess their performance. By carefully evaluating these factors and understanding the specific application requirements, we can confidently select the right sandblast equipment that maximizes productivity, delivers the desired finish, and ensures safe and efficient surface treatment.

Limitations and Overcoming Them

Sandblast equipment, though invaluable, comes with certain limitations and challenges that manufacturers are diligently addressing. A primary concern is the dust and debris generated during sandblasting, which poses health risks to workers and environmental issues. To mitigate these risks, manufacturers are developing advanced dust collection and containment systems, ensuring a safer work environment. Additionally, they are investigating environmentally-friendly abrasive alternatives to minimize hazardous dust production. Surface damage, particularly on delicate materials, remains a challenge; however, modern equipment now features adjustable pressure settings and precise controls for safer blasting. Efforts to recycle and reclaim used abrasive media are also underway, reducing waste and operational costs. Furthermore, manufacturers are integrating noise reduction features and automation with robotics to tackle noise pollution and enhance overall efficiency. Through continued research and development, manufacturers aim to deliver safer, more efficient, and eco-friendly sandblast equipment for a variety of applications.

Training and Certification

Training and certification for operators of sandblast equipment are essential for ensuring the safe and proficient use of the machinery. A comprehensive training program should encompass both theoretical knowledge and practical hands-on experience. Operators must grasp the fundamentals of sandblasting, including the various types of abrasive media, the equipment’s components and functionalities, and the necessary safety precautions to protect themselves and others.

Our practical training should encompass demonstrations of proper equipment setup, operation, and maintenance. This includes learning how to adjust pressure settings, control abrasive flow, and effectively direct the blasting stream for various surface materials and coatings. Through hands-on practice, operators can develop the necessary skills and dexterity to perform sandblasting tasks accurately and efficiently.

Safety training is a crucial part of preparing operators. It should encompass respiratory protection to shield against airborne particulates, proper use of personal protective equipment (PPE), and guidelines for handling hazardous materials. Operators need to be educated on setting up effective ventilation and containment systems to manage dust and debris generated during sandblasting operations.

Certifications are usually acquired through reputable industry organizations or training institutes. The process involves evaluating an operator’s knowledge, skills, and adherence to safety practices. By becoming certified, operators gain a competitive edge in the job market and show their dedication to upholding high standards of safety and professionalism.

Employers frequently prioritize hiring certified operators to ensure a competent and knowledgeable workforce. Certified operators help reduce the likelihood of accidents, minimize the risk of equipment damage, and enhance overall operational efficiency.

Continuing education and regular refresher courses are crucial for keeping us, the operators, up-to-date with advancements in sandblast equipment technology and safety protocols. Staying informed about industry best practices helps us maintain our certification status and ensures we can effectively adapt to evolving industry standards.

Investing in comprehensive training and certification for sandblast equipment operators is a proactive step that enhances workplace safety, reduces risks, and boosts the success and reputation of businesses in the sandblasting industry.

Benefits of Sandblast Equipment

Despite these limitations, sandblast equipment offers several advantages. One of the primary benefits is its efficiency in removing rust, paint, and other coatings from surfaces, making it an excellent choice for surface preparation before painting or other treatments. In addition to this generic benefit, there are more concrete benefits to examine including:

Cost-effectiveness: Sandblast equipment offers a cost-effective solution for removing paint, rust, and other coatings from surfaces. It serves as a one-time investment that can be utilized repeatedly, eliminating the need for costly chemical treatments or frequent equipment replacements.

Time-efficiency: Sandblast equipment is a time-efficient method for cleaning and preparing surfaces. Compared to manual techniques like sanding or scraping, sandblasting allows us to cover a larger surface area in a much shorter amount of time.

Versatility: Sandblast equipment is highly versatile, serving a wide range of industries and applications. It’s suitable for various materials and surfaces, making it an indispensable tool.

Eco-friendliness: Sandblast equipment serves as an eco-friendly alternative to chemical treatments, which often harm the environment. By using natural abrasive materials like sand or glass beads, which can be reused and recycled, sandblasting offers a sustainable solution.

Non-toxicity: It operates without the use of chemicals or solvents, making it a non-toxic method for cleaning and preparation. This ensures a safer environment for workers and reduces harm to the planet.

Consistency: Sandblast equipment delivers consistent results, which is vital for applications in industries like aerospace or automotive, where precision and uniformity are essential.

Applications of Sandblast Equipment

Sandblast equipment finds use in a multitude of industries and applications. Among the businesses utilizing this equipment are the automotive and aerospace sectors. Additionally, sandblast equipment plays a crucial role in surface preparation, cleaning and restoring buildings and monuments, and etching and engraving glass. Below, we delve into these diverse uses and applications.

Surface preparation for painting: They commonly use sandblast equipment to prepare surfaces for painting by removing old paint, rust, or other coatings. This process ensures that the surface is clean and smooth, allowing for better adhesion of the new paint.

Cleaning and restoring buildings: Sandblast equipment is ideal for cleaning and restoring building exteriors, including those made of brick, stone, and concrete. It’s also effective for removing graffiti and other types of vandalism.

Automotive restoration: In the automotive industry, they use sandblast equipment to strip away paint, rust, and other coatings from a car’s body during restoration.

Aerospace industry: They use sandblast equipment in the aerospace industry to prepare aircraft surfaces for painting or to remove corrosion. Additionally, we use it to clean turbine blades and other components.

Glass etching and engraving: Sandblast equipment is used to create intricate designs and patterns on glass surfaces, like windows, doors, and mirrors.

Monument and statue restoration: They use sandblast equipment to clean and restore historical structures, removing paint and rust from statues and monuments.

Choosing the Right Sandblast Equipment Supplier

To achieve the best results when purchasing sandblast equipment, it’s essential to compare multiple suppliers using our directory. Each supplier has a detailed business profile page showcasing their expertise and capabilities, along with a contact form for direct communication or quote requests. Utilize our proprietary website previewer to swiftly understand each company’s specialties. Then, use our streamlined RFQ form to reach out to several sandblast equipment suppliers simultaneously.

Deburring Machinery

Deburring Machinery Industrial Parts Washers

Industrial Parts Washers Sandblast Equipment

Sandblast Equipment Ultrasonic Cleaners

Ultrasonic Cleaners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services