A bead blaster uses high pressure to fire media in the shape of beads at the surface of the substance. Fine glass beads are released under great pressure during this technique to clean or polish a surface. In industrial, commercial, and home contexts, bead blasters use high-pressured streams of spherical abrasives to clean or otherwise resurface surfaces and components. The goal of a bead blast finish is to produce a surface that is bright, smooth, and clean. Read More…

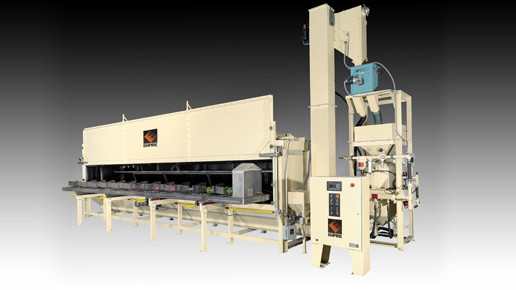

Our sandblast equipment is designed to handle a wide variety of applications and we use manufacturing methods that guarantee these machines will stand the test of time.

We have decades of experience in the finishing industry and we specialize in aqueous washing, abrasive blasting, vibratory finishing, polishing and buffing.

With over 100 years of combined dust-collecting experience, Rapid Prep LLC is a leader in the dust-collecting and sandblast equipment industry. We offer a wide range of products to meet the needs of our customers, with customization options available. Our team is dedicated to advancing our company and raising industry standards.

Cardinal Parts & Equipment LLC specializes in designing high-quality abrasive blasting equipment. The equipment they offer includes tumble blast equipment, rim blast equipment, dust collectors, and hanger blast equipment. They also sell abrasives like steel shot, stainless steel shot, and cast zinc shot. Their services include service calls, inspections, financing, and equipment rebuilding....

More Bead Blaster Manufacturers

How Bead Blasters Work

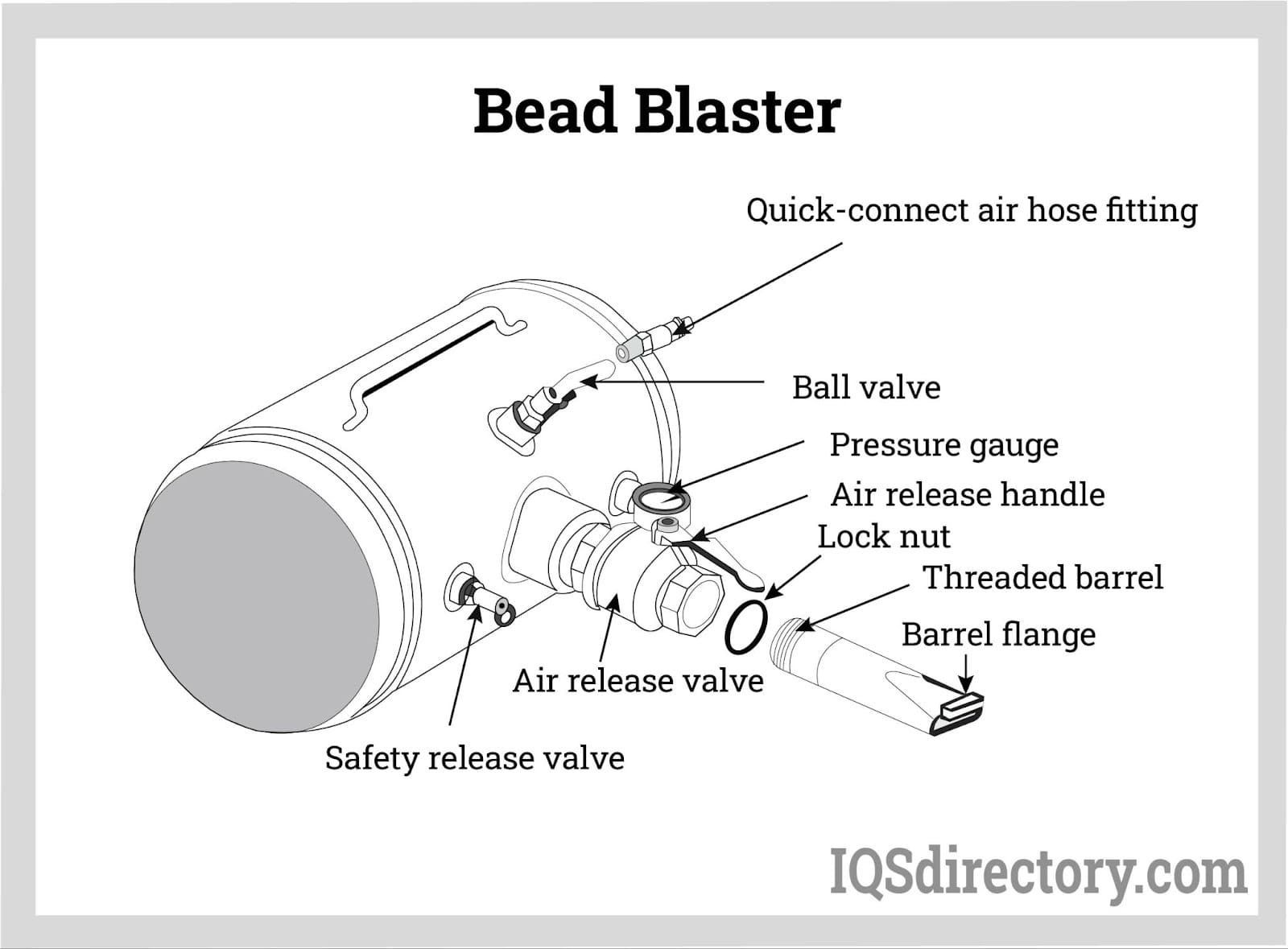

Even though individual machines may vary, most bead blasters are built similarly. A power supply and a hopper or jar containing abrasive beads are coupled to an air compressor. A shot blaster gun is connected to the hopper by hoses of various lengths. If the beads are to be collected for reuse and, if size permits, the gun and nozzle may be contained in a blast booth or cabinet.

The air compressor sends air into the gun when a trigger is pulled or a switch is pressed, generating a vacuum. With the help of the vacuum, the abrasive beads are drawn through the tube and out of the gun's nozzle in a high-pressure stream that is directed towards the surface that needs to be cleaned or resurfaced. Along with flow rate and blast pressure, it is important to carefully evaluate the materials of the item and the beads.

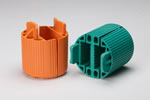

The size of the beads might also vary based on the requirements of a particular application and the production processes. There are numerous techniques to create abrasive beads made of plastics, ceramics, glassware, and metals like aluminum oxide, silicon carbide, acrylics, aluminum, brass, and bronze.

How to Get the Best Finish With Bead Blasting

- Use low pressure for bead blasting: The first piece of advice is to lower the bead blaster's pressure; 50 PSI (3.5 Bar) is typically a good place to start. Be aware that low pressures are better for using glass beads. The pressure should be as minimal as feasible as a result. By doing so, one can improve the metal's surface finishing and lengthen the time the beads stay in place. The best outcome will be obtained with a siphon blaster at 50 PSI pressure. Glass beads cannot be cut due to their design. They are designed to burnish or polish a part instead. They do this, though, at a faster rate than other tumbling media. The beads start to break when they collide with the component as soon as their pressure is increased.

- Aluminum cannot be bead blasted to a nice finish without first having its oxide coating stripped off. Usually, the oxide coating is too tough to burnish or polish. Additionally, it could make stains difficult to clean up. It may have some shine, but it will appear to have shine stains. Be aware that glass beads will not assist with removing or stripping off the oxide coating. This is because they cannot cut, per their design. To remove the oxide or rust, it will be helpful to apply a sharp, cutting abrasive. One can remove rust and oxides with crushed glass, black beauty aluminum oxide, etc. Because it works quickly, like silicon carbide or aluminum oxide, shattered glass is a desirable option. Additionally, it leaves metals with a nicer, brighter polish and is highly clean. Whatever abrasive a user decides to use to remove oxides, a substance with consistency is ideal. One can remove heavier scales with ease by using some coarse bracing and an abrasive.

Applications of Bead Blasters

- Shot blasters that use beads have the unique ability to dimpling the substrate to impart compressive residual surface stress while decreasing tensile strength, greatly increasing fatigue strength. The use of rounded beads is essential for this result because angular and sharp-edged grit blasters do not produce these specific material advantages even though they are good at cleaning and resurfacing.

- The adaptability offered by bead-blasting equipment is utilized by the automotive, shipbuilding, electronics, construction, agriculture, industrial cleaning and processing, aerospace, decorative design, woodworking, and glass industries.

- Gears, shafts, housings, and turbine blades all benefit greatly from bead blasting in terms of increased durability. Nuts, bolts, printed circuit boards, ships, bridges, and construction components are just a few examples of the different industrial components whose quality is improved.

- Bead blasting is a quick and dust-free procedure that reduces the health risks related to inhaling silica dust, even though conventional sand and grit blasters can be utilized in certain applications.

Choosing the Correct Bead Blaster Manufacturer

To make sure you have the most productive outcome when purchasing bead blasters from a bead blaster manufacturer, it is important to compare at least four manufacturers using our bead blaster directory. Each bead blaster manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each bead blaster company using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple bead blaster companies with the same quote.

Deburring Machinery

Deburring Machinery Industrial Parts Washers

Industrial Parts Washers Sandblast Equipment

Sandblast Equipment Ultrasonic Cleaners

Ultrasonic Cleaners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services