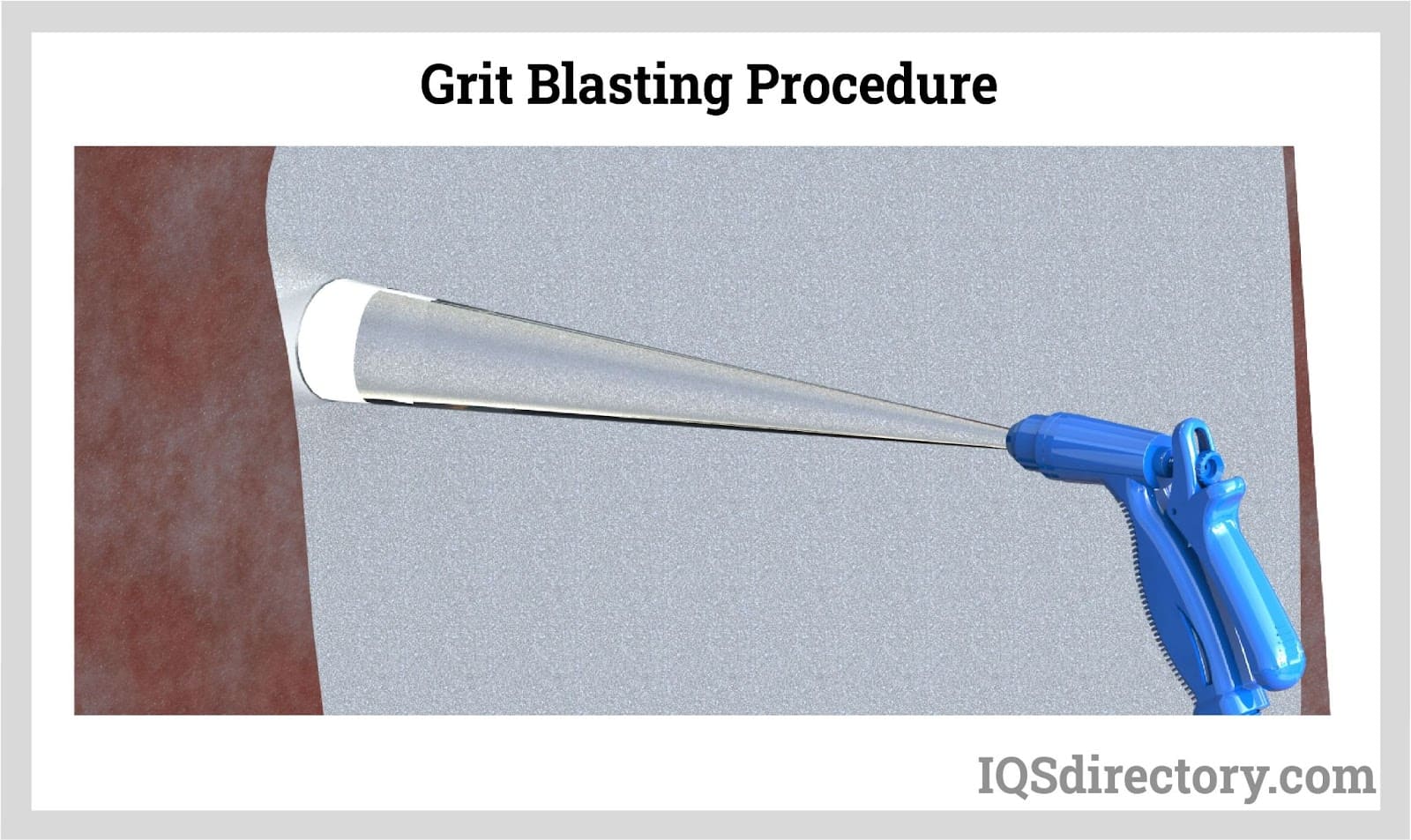

Grit blasting is a technique that uses the impact of hard particles to produce surface patterns. High-velocity particles distort a metal surface locally by plastic deformation. The size, hardness, form, and velocity of the shot particles when using high-speed particles all have an impact on the final texture. Read More…

Our sandblast equipment is designed to handle a wide variety of applications and we use manufacturing methods that guarantee these machines will stand the test of time.

We have decades of experience in the finishing industry and we specialize in aqueous washing, abrasive blasting, vibratory finishing, polishing and buffing.

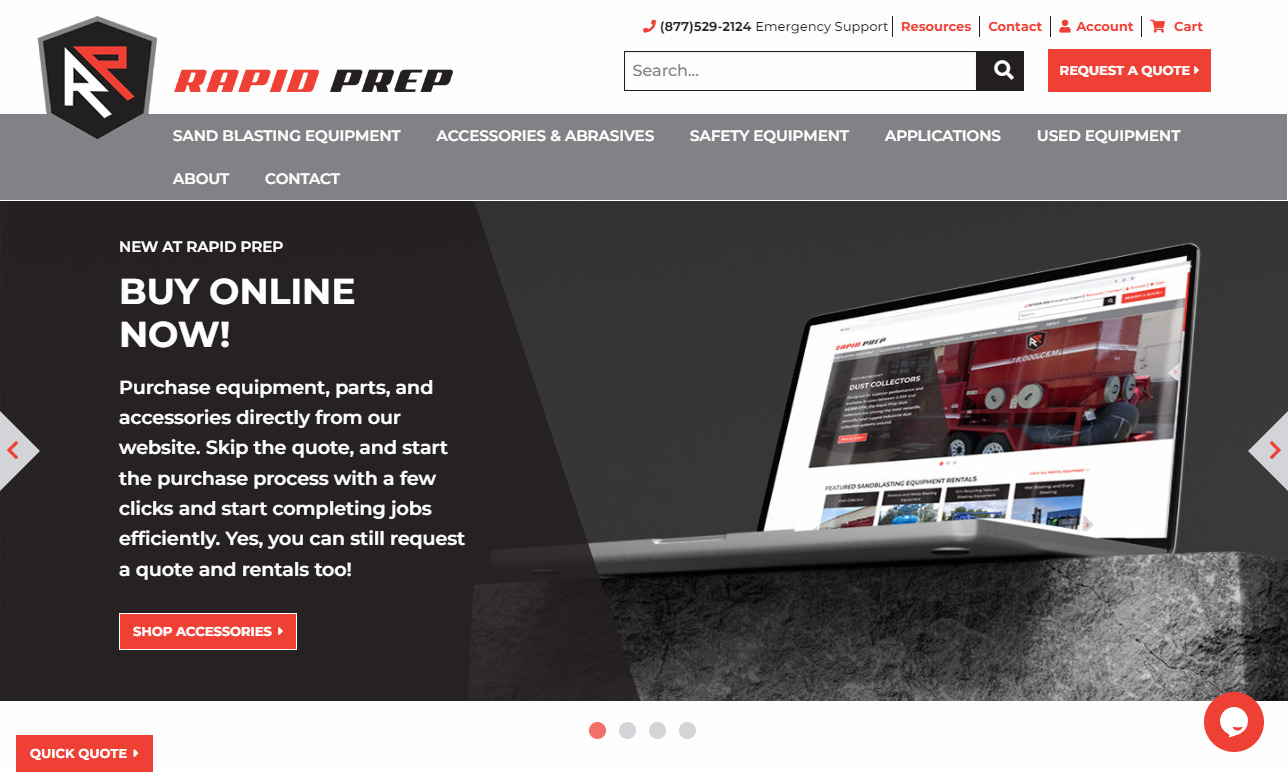

With over 100 years of combined dust-collecting experience, Rapid Prep LLC is a leader in the dust-collecting and sandblast equipment industry. We offer a wide range of products to meet the needs of our customers, with customization options available. Our team is dedicated to advancing our company and raising industry standards.

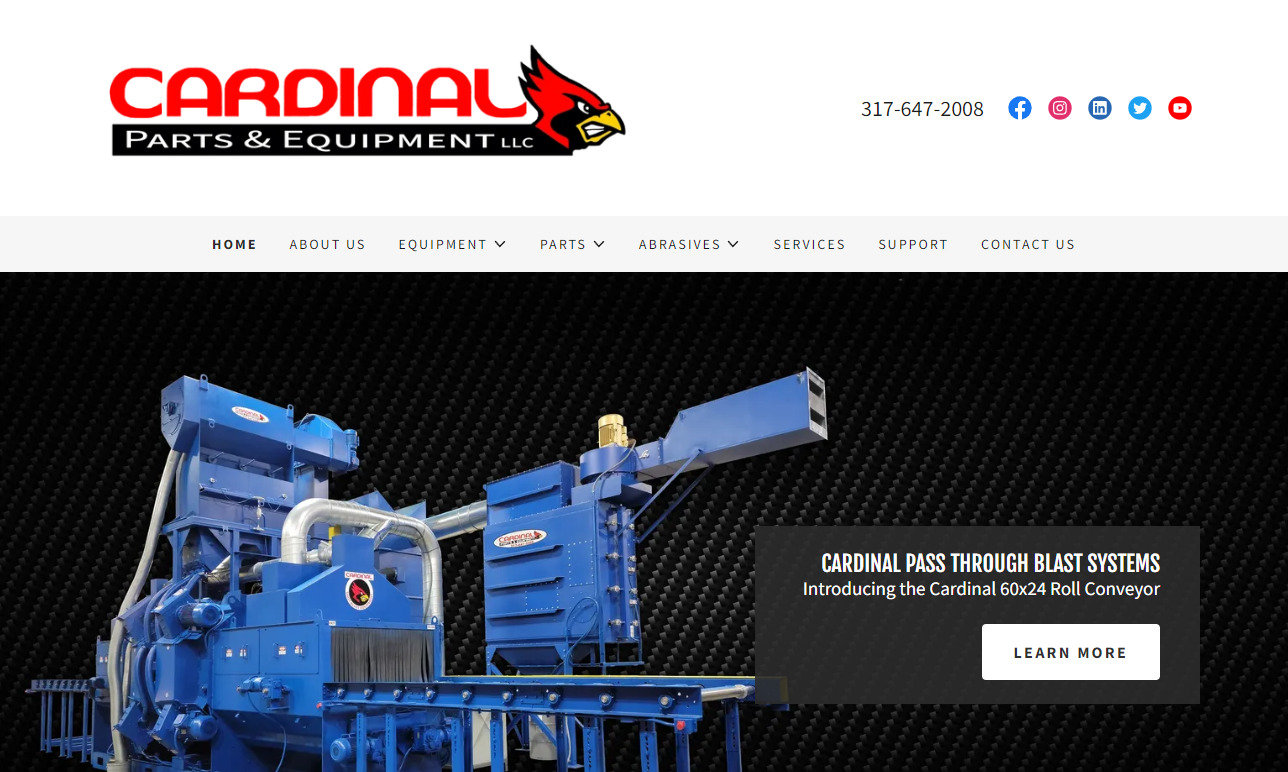

Cardinal Parts & Equipment LLC specializes in designing high-quality abrasive blasting equipment. The equipment they offer includes tumble blast equipment, rim blast equipment, dust collectors, and hanger blast equipment. They also sell abrasives like steel shot, stainless steel shot, and cast zinc shot. Their services include service calls, inspections, financing, and equipment rebuilding....

More Grit Blaster Manufacturers

Impact from hard-shot particles can produce dimple textures. The most popular surface texturing technique is grit blasting because it produces a rough surface with little effort and is simple to utilize in industrial settings. The strength of the pressure streams varies according to the surface type and grit being employed. What results is a task that would need hours of manual sanding may be completed in a matter of minutes.

How Grit Blasting Works

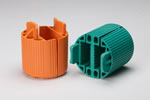

Even though they are sometimes mistaken for sandblasters, grit blasting operations use a wide range of abrasive media to complete task-specific activities. For instance, silicon carbide, a very tough ceramic grit, is used to scrub strong surfaces like steel. Meanwhile, baking soda is a gentle abrasive that can be used on delicate materials. Numerous additional grit media are also employed, such as silica sand, aluminum, carbide, ceramics, copper, glass, iron, gold, plastic, steel, wood, and even nut and fruit kernel shells. These substances are broken down into a thin dust or powder with varying-sized grains by flaking, pulverizing, atomizing, or some other method.

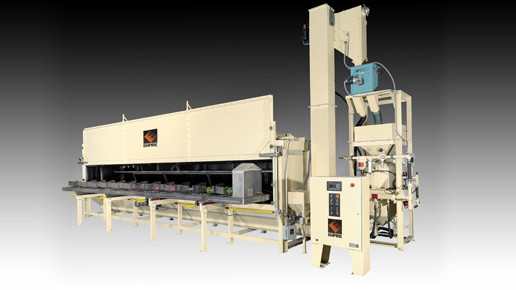

When choosing a grit blaster, the type of grit material is crucial because some can handle only one type while others are multi-media. In either case, this sandblasting equipment serves the same fundamental purpose. A power source, a hopper or vessel containing abrasives, and a pressure generator are all connected. If the grit is to be collected for reuse and, if size allows, hoses of varied lengths link the hopper to a nozzle that may be housed in a sandblast cabinet.

A vacuum is created when a trigger is pulled or a switch is pressed, forcing air or water through the gun and out the nozzle in a high-pressure stream that is directed towards the substrate that needs to be cleaned or resurfaced. Although this is a basic description, particular machines will differ and should be taken into account in regard to the process's intended objectives.

Applications of Grit Blasters

- Grit blasters produce a pressurized stream that can be adjusted to perform a variety of tasks, including removing coatings, smoothing rough surfaces, etching smooth surfaces, carving rough surfaces, degreasing, deburring, peening, deflashing, and descaling machinery and parts made of metal, wood, plastic, and glass. These machines have a variety of uses in various sectors since they may be used to maintain both heavy-duty and precise parts.

- In order to improve performance and completely prevent any possibility of harm to the product or part being handled, it is crucial to take into account the blast pressure and level of abrasiveness because both the abrasives and the material composition of the receiving substrates vary.

Advantages of Grit Blasting

- In relation to the aforementioned aspect, the bond for the surface after cleaning is crucial. Any fresh paint, seal, or protective coating will adhere better because blasting is a more natural process. The link between the surface and coating may not be as strong and hence may not hold up as well if chemicals are used to clean the surface.

- It is considerably easier to make patterns with blasting than it is with other procedures since it offers a wider selection of abrasive materials and the opportunity for higher accuracy. Blasting provides the greatest choice for users wanting to be creative with the surface being cleaned.

- There is no better alternative because the primary concept in grit and shot blasting is abrasion. Other methods would involve the use of chemicals and acids, which are more difficult to dispose of and hazardous to the environment. Grit and shot blasting produce the same effects, but there is less waste because the pellets and dust can be vacuumed up. These materials are frequently recycled. While blasting and chemicals both accomplish the same task, it's crucial to remember that chemicals have the potential to affect the surface and any newly placed coating.

Choosing the Right Grit Blaster Supplier

To make sure you have the most positive outcome when purchasing grit blasters from a grit blaster supplier, it is important to compare at least four companies using our grit blaster directory. Each grit blaster supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each grit blaster business website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple grit blaster companies with the same quote.

Deburring Machinery

Deburring Machinery Industrial Parts Washers

Industrial Parts Washers Sandblast Equipment

Sandblast Equipment Ultrasonic Cleaners

Ultrasonic Cleaners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services