Sandblast cabinets are equipment used to blast material against a part’s surface to abrade, clean, or change the surface. Manufacturers use pressured water, compressed air, or a blast wheel to propel sand, abrasive material, metal shot, and other blast media. Sandblast cabinets are metal boxes with windows, apertures, and gloves attached. Sand or another abrasive material is used in the sandblast cabinet to smooth off rough surfaces and remove metal flaws and scraps of old paint or corrosion. The metal frame and body construction influence the quality and longevity of sandblasting cabinets. Sandblasting cabinets are often made of durable, heavy gauge steel. Read More…

Our sandblast equipment is designed to handle a wide variety of applications and we use manufacturing methods that guarantee these machines will stand the test of time.

We have decades of experience in the finishing industry and we specialize in aqueous washing, abrasive blasting, vibratory finishing, polishing and buffing.

With over 100 years of combined dust-collecting experience, Rapid Prep LLC is a leader in the dust-collecting and sandblast equipment industry. We offer a wide range of products to meet the needs of our customers, with customization options available. Our team is dedicated to advancing our company and raising industry standards.

Cardinal Parts & Equipment LLC specializes in designing high-quality abrasive blasting equipment. The equipment they offer includes tumble blast equipment, rim blast equipment, dust collectors, and hanger blast equipment. They also sell abrasives like steel shot, stainless steel shot, and cast zinc shot. Their services include service calls, inspections, financing, and equipment rebuilding....

More Sandblast Cabinet Manufacturers

How Sandblast Cabinets Work

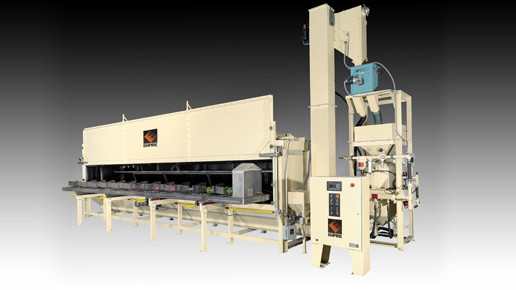

A sandblast cabinet has a container, an abrasive media blasting system, an abrasive media recycling system, and a dust collection section. It is a closed-loop system because operators can recycle the abrasive material used to blast the component. By putting his arms in gloves attached to glove holes on the cabinet, looking at the component through a view window, and often turning the blast on and off using a bottom pedal or treadle, the operator drafts the parts from the shape of the cabinet. In a sandblasting cabinet, loose grains (abrasives) are accelerated by compressed air to perform various tasks, including sanding, deburring, polishing, texturing, removing surface material, and even coating items with a lubricant that is permanently blasted into their surface.

Types of Sandblasting Cabinets

Siphon Blasting Cabinets

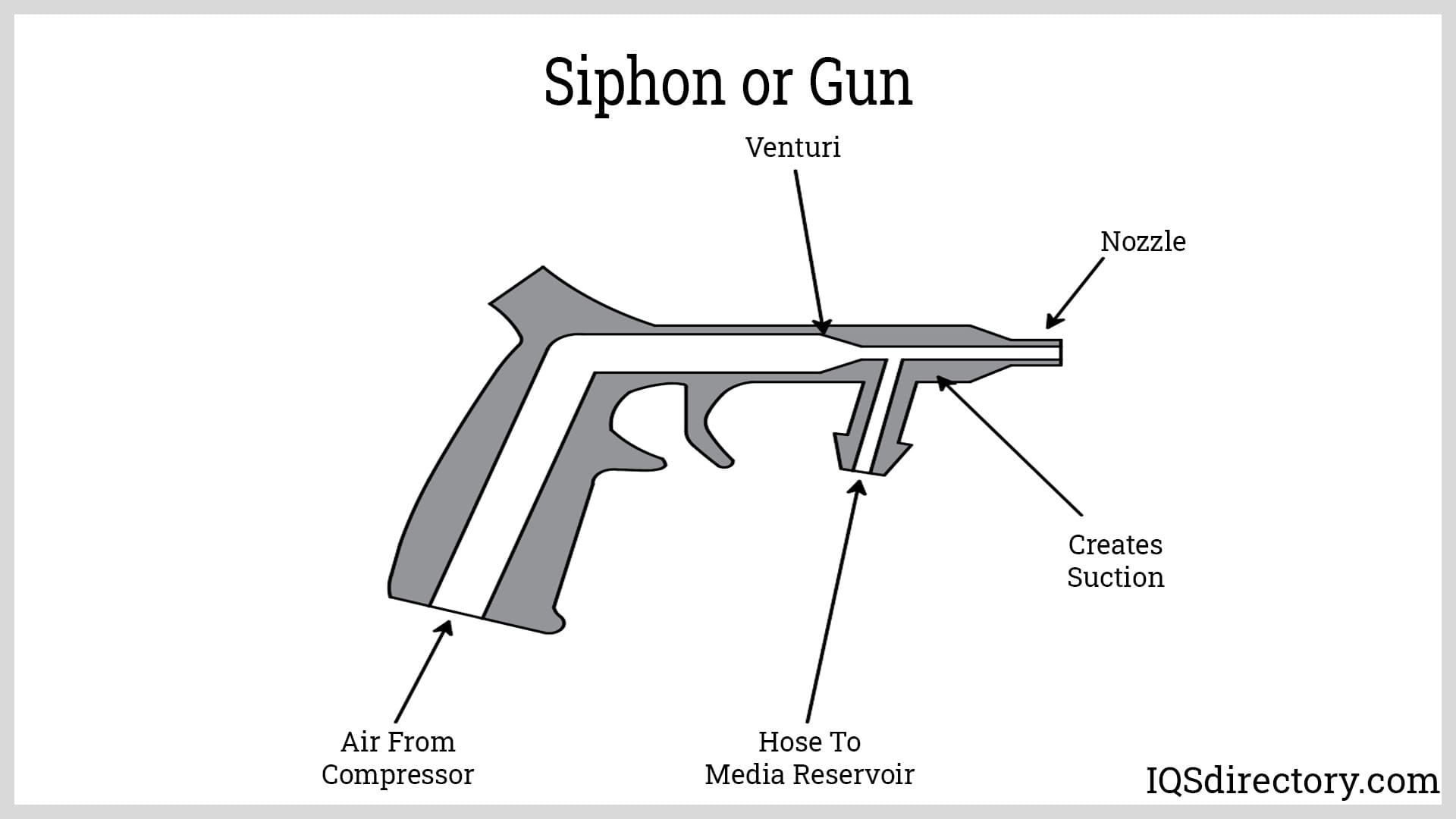

Suction cabinets commonly called siphons, are excellent for occasional use, general cleaning, and low-intensity production tasks. They insert abrasive media into your blasting nozzle using a gun. Because the distribution is a two-step operation, greater air pressure is needed than with direct-pressure cabinets. Suction blasters are used in remote field applications, maintenance, and short-run or light production. Suction blasters take longer to clean parts because they are less forceful.

On the plus side, a suction blaster's component wear rate is decreased by the lesser aggressiveness. As a result, suction blaster parts typically last longer, lowering the cost of maintaining blast equipment. These suction cabinet systems are affordable and easy to install.

Direct Pressure Cabinets

In direct pressure cabinets, a pressure vessel activates the abrasive material. The pressure vessel's pop-up or metering valve opens to let pressurized fluid and blast media flow into a blast hose. These machines expel abrasive media at a higher blasting flow rate than siphon blasting cabinets. As a result, they get jobs done quicker. The blast hose connects the direct pressure cabinet and blast gun with the pressurized media. The pressure can be adjusted to change the flow rate for each job.

Wet Sandblast Cabinets

In wet sandblast cabinets, water is used to power the blast media. When stripping or cleaning a part containing heavy metals and hazardous compounds, wet abrasive or water blasting can minimize the dust produced during abrasive blasting by over 90%. Wet blasting uses a water-abrasive mixture for a smoother surface and less cabinet-inside dust.

Water effectively removes grease and oil-based pollutants, whereas dry blasting grease & oil could lead to abrasive coagulation and equipment failure. Wet blasting is often used to restore motor and compressor parts. To liquefy oils or greases, dissolve deposits, and speed up cleaning, one can add detergents to water.

Portable Sandblast Cabinets

Portable sandblaster cabinets, also known as mini sandblasters, are ideal for working with smaller or more delicate objects since they allow more precision. Additionally, benchtop sandblast cabinets are mobile, allowing you to conduct tasks outside your workshop or garage. They may be operated remotely and are typically less expensive than other sandblaster cabinets.

Advantages of Sandblasting Cabinets

Simple to Operate: Sandblasting cabinets are simple to use and don’t require much technical expertise.

Versatility and Utility: Sandblasting cabinets have many uses; vastly different industries incorporate them into daily operations.

Installation Requirements Are Low: A nozzle, a blasting pot, and a compressor are the only tools needed to operate a sandblast cabinet. The components can alter depending on the use for which these cabinets are intended.

Reliable Results: Sandblast cabinets clean hard surfaces thoroughly and guarantee a spotless finished surface.

Choosing the Correct Sandblast Cabinet Manufacturer

To make sure you have the most beneficial outcome when purchasing sandblast cabinets from a sandblast cabinet manufacturer, it is important to compare at least five manufacturers using our list of sandblast cabinet manufacturers. Each sandblast cabinet company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each sandblast cabinet company website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple sandblast cabinet companies using the same message.

Deburring Machinery

Deburring Machinery Industrial Parts Washers

Industrial Parts Washers Sandblast Equipment

Sandblast Equipment Ultrasonic Cleaners

Ultrasonic Cleaners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services