Sandblasters are used for a wide range of tasks, such as removing coatings, roughening smooth surfaces, smoothing rough surfaces, etching, carving, degreasing, deburrying, peening, deflashing and descaling equipment and parts made of metal, wood, plastic and glass. Read More…

Our sandblast equipment is designed to handle a wide variety of applications and we use manufacturing methods that guarantee these machines will stand the test of time.

We have decades of experience in the finishing industry and we specialize in aqueous washing, abrasive blasting, vibratory finishing, polishing and buffing.

With over 100 years of combined dust-collecting experience, Rapid Prep LLC is a leader in the dust-collecting and sandblast equipment industry. We offer a wide range of products to meet the needs of our customers, with customization options available. Our team is dedicated to advancing our company and raising industry standards.

Cardinal Parts & Equipment LLC specializes in designing high-quality abrasive blasting equipment. The equipment they offer includes tumble blast equipment, rim blast equipment, dust collectors, and hanger blast equipment. They also sell abrasives like steel shot, stainless steel shot, and cast zinc shot. Their services include service calls, inspections, financing, and equipment rebuilding....

More Portable Sand Blaster Manufacturers

The versatility of portable sandblasting equipment allows heavy use of these mechanisms in automotive, shipbuilding, construction, agriculture, industrial cleaning and processing, aerospace, decorative design, woodworking and glass industries. Portable sandblasters are particularly useful in industrial and personal settings as they allow a single machine to be used in a variety of locations, moving from workstation to workstation.

While smaller models are used to rework small parts such as nuts, bolts, decorative glass, printed circuit boards and engine components, large models handle the resurfacing of ships, bridges, tractors, building components, aircraft and heat exchangers. The method of mobility is heavily dependent upon the size of a given machine.

Smaller units can be lightweight and handheld or mounted to benches, pedestals, carts or skids with casters allowing them to roll easily from one worksite to another. Large industrial models, however, are frequently mounted to a trailer or vehicle and then driven from one location to another.

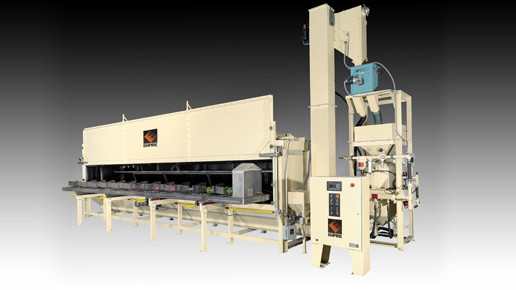

Though design can vary significantly, most portable sandblasters have the same general operating components. Each unit must have a power supply, pressure generator or air compressor, crankshaft or plunger pump, abrasive injector, blaster nozzle, a vessel to hold the abrasive media and in some instances dust collection units or media separators. The system works by compressing air or pressurizing liquid which in turn pushes or pulls an abrasive media out of the containment vessel and through the nozzle.

The head of the nozzle directs a stream of highly pressurized materials at the surface to be reworked. While many portable units are operated in an open environment, others have a blast cabinet. This cabinet houses the head of the nozzle and is made of durable metals and plastics that can withstand high pressure blasts of abrasive materials. The object to be sandblasted is placed inside and treated within the cabinet. Alternatively, units without an attached blast area are used on freestanding objects that are too large or cumbersome to be placed in a blast room.

Although sandblasting has become the popular term for this particular type of machinery, media blasting is more applicable as silica sand is only one of the many types of both rounded and angular abrasives frequently used. Alternative materials include balled, ground, flaked or granulated particulates of such diverse materials as aluminum, carbide, ceramic, copper, glass, iron, gold, plastic, steel, wood, acrylic and baking soda. As portable sand blasters are often multi-purpose, many have multi-media capabilities as well.

Deburring Machinery

Deburring Machinery Industrial Parts Washers

Industrial Parts Washers Sandblast Equipment

Sandblast Equipment Ultrasonic Cleaners

Ultrasonic Cleaners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services