A bead blaster uses high pressure to fire media in the shape of beads at the surface of the substance. Fine glass beads are released under great pressure during this technique to clean or polish a surface. In industrial, commercial, and home contexts, bead blasters use high-pressured streams of spherical abrasives to clean or otherwise resurface surfaces and components. The goal of a bead blast finish is to produce a surface that is bright, smooth, and clean. Read More…

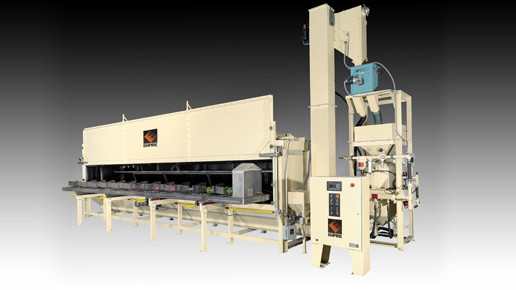

Our sandblast equipment is designed to handle a wide variety of applications and we use manufacturing methods that guarantee these machines will stand the test of time.

We have decades of experience in the finishing industry and we specialize in aqueous washing, abrasive blasting, vibratory finishing, polishing and buffing.

We are SurfacePrep, a trusted leader in surface preparation solutions, dedicated to delivering high-performance sandblast equipment and related products that meet the demanding needs of our customers. Our focus is on providing reliable, innovative equipment and consumables that help businesses achieve optimal surface finishes, improve efficiency, and extend the life of their tools and machinery.

At Allredi, we pride ourselves on being a leading provider of sandblast equipment, delivering exceptional solutions to meet the diverse needs of our customers. Our extensive range of products includes innovative sandblast machines, nozzles, and abrasives, all designed to enhance efficiency and performance in various applications.

At Raptor Blasting Systems, we are dedicated to designing and manufacturing high-quality sandblast equipment built to deliver exceptional performance and reliability for industrial applications. With years of expertise, we have refined our engineering processes to produce blasting cabinets, pressure systems, and abrasive recovery solutions that meet the rigorous demands of our customers.

More Bead Blaster Manufacturers

How Bead Blasters Work

Bead blasters, also known as bead blasting machines or abrasive bead blasting systems, are essential industrial tools used to clean, finish, and resurface a variety of materials. While individual machines may have unique features, most bead blasters operate on similar principles. Central to every bead blaster is a robust power supply and an abrasive media hopper—sometimes referred to as a bead jar—that contains the blasting beads. These abrasive beads can be composed of glass, ceramic, plastic, or metallic materials like aluminum oxide or silicon carbide, depending on the desired finish and application.

An air compressor powers the system, sending compressed air into the bead blaster gun when the user pulls a trigger or presses a switch. This action creates a vacuum, drawing the abrasive beads through a hose and expelling them from the nozzle as a high-pressure stream. This stream is then precisely directed at the target surface, effectively removing surface contaminants, old paint, rust, scale, and oxidation, or providing a uniform finish. Factors like blast pressure, flow rate, bead size, and media type must be carefully matched to the material and specific job requirements for optimal results.

Bead blasting equipment can be configured as portable units, blast cabinets, or blast booths. For applications where bead recovery and environmental control are critical, enclosed bead blasting cabinets capture and recycle the abrasive media, improving cost-efficiency and reducing waste. Hoses of varying lengths connect the hopper to the blast gun, allowing flexibility in use and movement. Some advanced systems even use automated robotic arms for high-volume production environments.

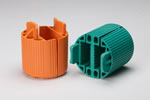

The abrasive beads themselves vary in size and hardness to suit diverse industrial applications. Common bead materials include:

- Glass beads: Provide a smooth, satin finish ideal for cleaning and cosmetic applications.

- Ceramic beads: Offer higher durability and are suitable for tough, heavy-duty blasting.

- Plastic beads: Used for delicate substrates or where minimal surface impact is required.

- Metallic beads (such as aluminum oxide, silicon carbide, steel shot, brass, and bronze): Deliver aggressive cleaning and texturing, often used in peening and surface preparation for coatings.

Whether used for surface preparation, rust removal, deburring, or finishing, bead blasters are valued for their versatility and efficiency across multiple industries. Want to learn more about how bead blasters can be tailored for your specific project or material? Explore common bead blasting applications below.

How to Get the Best Finish With Bead Blasting

Achieving a superior surface finish with bead blasting requires careful attention to technique, equipment settings, and media selection. Here are key tips and best practices for maximizing the quality and consistency of your bead blasting results:

- Start with low blast pressure: For most applications, especially when using glass bead blasting media, begin with lower pressure settings—around 50 PSI (3.5 Bar) is a common starting point. Lower pressures minimize surface damage, prevent bead fracturing, and produce a finer, more uniform finish. This is especially important for delicate parts or when a polished, burnished look is desired. Using a siphon blaster at 50 PSI typically yields optimal results for glass bead applications.

- Match abrasive media to the substrate: Not all materials respond the same way to bead blasting. For example, aluminum surfaces often have a hard oxide layer that is difficult to remove with glass beads alone. To strip oxides or rust, it's best to start with a sharper, cutting abrasive (like aluminum oxide, silicon carbide, or crushed glass) before switching to glass beads for finishing and polishing. Consistent abrasive properties—such as uniform bead size and hardness—ensure repeatable results and minimize the risk of surface inconsistencies.

- Consider media recycling and cleanliness: Reusing beads can be cost-effective, but degraded media can produce inconsistent finishes or embed contaminants. Regularly inspect and refresh your blasting media to maintain quality. Using closed-loop bead blasting cabinets with integrated dust collection systems can further improve cleanliness and operator safety.

- Control blast angle and distance: Maintaining a consistent angle (usually 45-60 degrees) and distance between the nozzle and the workpiece helps distribute the abrasive beads evenly, preventing streaks and excessive wear.

- Optimize nozzle selection: The size and shape of the nozzle influence blast pattern and intensity. For intricate or small parts, use fine nozzles to achieve detailed cleaning, while larger nozzles cover broader surfaces efficiently. Consider using a tungsten carbide or boron carbide nozzle for longer life in high-volume blasting operations.

For those new to bead blasting, you may be wondering:

- What is the best bead blasting media for my material?—It depends on your substrate (metal, plastic, glass, etc.), desired finish, and whether you need aggressive cleaning or gentle polishing.

- How do I prevent warping or surface damage during bead blasting?—Careful pressure control, appropriate media selection, and proper technique are key.

- Can bead blasting be used for paint or coating preparation?—Absolutely. Bead blasting is widely used for preparing surfaces before painting, powder coating, or plating, ensuring optimal adhesion.

If you need personalized guidance on selecting the right bead blasting technique or troubleshooting finish issues, contact our bead blasting experts.

Applications of Bead Blasters

Bead blasters offer unmatched versatility across a wide range of industries and use cases. Here are some of the most common—and most valuable—applications for bead blasting technology:

- Surface preparation for coatings and painting: Bead blasting is a preferred method for cleaning and texturizing surfaces prior to applying paint, powder coatings, or other finishes. The process removes oils, rust, scale, and previous coatings, creating an ideal profile for maximum coating adhesion and longevity.

- Peening and fatigue strength enhancement: Shot blasters using rounded beads impart compressive residual stresses to metal substrates—a process known as shot peening. This significantly increases fatigue resistance and lifespan of critical components, such as automotive and aerospace parts, by reducing the likelihood of crack initiation. Unlike angular grit media, rounded bead blasting media do not introduce micro-cracks, making them ideal for high-performance parts.

- Automotive and aerospace industries: Automotive manufacturers, aircraft engineers, and restoration specialists rely on bead blasters for cleaning engine parts, refurbishing wheels, removing corrosion from chassis components, and preparing surfaces for welding or bonding. Bead blasting is also used to clean pistons, cylinder heads, and delicate aluminum parts without causing dimensional changes.

- Industrial and manufacturing cleaning: Bead blasters are essential in the maintenance of gears, shafts, housings, turbine blades, and valves, providing both cleaning and surface conditioning. Facilities such as food processing plants, chemical manufacturers, and electronics producers use bead blasting to remove contaminants, burrs, and residues from intricate machinery and components.

- Decorative and aesthetic finishing: Bead blasting is valued for its ability to produce attractive, uniform matte or satin finishes on metal, glass, plastic, and even wood. Jewelry makers, artists, and designers use bead blasting to create unique textures and enhance product appearance.

- Glass etching and surface texturing: In the glass industry, bead blasters are used for decorative etching, frosted finishes, and anti-slip treatments on architectural and industrial glass panels.

- Medical device manufacturing: Bead blasting ensures a sterile, smooth surface on surgical tools, implants, and medical equipment—critical for both functionality and safety.

- Shipbuilding, construction, and infrastructure: Removing rust, marine fouling, and old coatings from ships, bridges, railings, and metal structures is streamlined with bead blasting, improving durability and reducing maintenance costs.

- Electronics and PCB cleaning: Printed circuit boards and electronic components are cleaned and deburred using fine bead blasting, which eliminates residues without damaging sensitive parts.

- Woodworking and antique restoration: Bead blasters gently remove old finishes and patina from wood surfaces and antiques, preserving intricate details and original craftsmanship.

Curious about whether bead blasting is right for your application? Ask yourself:

- What is the primary goal—cleaning, finishing, deburring, or peening?

- What type of substrate are you working with—metal, glass, plastic, wood?

- Do you need an automated or manual bead blasting system?

- Are dust control, noise reduction, or environmental containment important for your facility?

Benefits of Bead Blasting Over Other Abrasive Methods

Bead blasting offers several unique advantages compared to traditional sandblasting, shot blasting, or chemical cleaning methods. Key benefits include:

- Dust-free operation: Unlike sandblasting, bead blasting generates minimal dust, reducing health risks associated with inhaling fine silica particles and improving workplace safety.

- Consistent, non-aggressive finishing: Rounded beads polish and burnish rather than cut, making bead blasting ideal for delicate surfaces and precise finishing without removing excessive material or altering part dimensions.

- Environmentally friendly: Many bead blasting media (especially glass and ceramic beads) are reusable and recyclable, reducing waste and costs.

- Enhanced surface integrity: The process minimizes micro-cracking and work hardening, preserving the structural integrity of components.

- Broad compatibility: Bead blasters accommodate a wide variety of abrasive media, enabling customization for diverse materials and finishes.

Key Decision Factors When Selecting a Bead Blaster

Choosing the right bead blaster for your needs involves more than comparing price tags. Consider the following factors to ensure a wise investment that maximizes productivity and return on investment:

- Type of equipment: Decide between portable bead blasters, blast cabinets, or full-size blast rooms based on project size, frequency, and environmental controls.

- Media compatibility: Ensure the system supports your preferred abrasive media (glass, ceramic, plastic, or metallic beads) and offers easy media changeover if you use multiple types.

- Blast pressure and flow control: Look for adjustable pressure settings and precise flow controls to fine-tune performance for different materials and tasks.

- Ease of maintenance and media recycling: Features like integrated dust collection, separation systems, and easy-to-clean components reduce downtime and operating costs.

- Safety features: Prioritize equipment with robust safety interlocks, ergonomic controls, and proper ventilation—especially in high-volume or enclosed applications.

- Manufacturer reputation and support: Research supplier track records, read customer reviews, and verify the availability of technical support, replacement parts, and training.

Not sure which bead blaster is right for your workshop, factory, or restoration project? Connect with our consultants for a personalized recommendation.

Choosing the Correct Bead Blaster Manufacturer

To ensure you achieve the best results when investing in bead blasting equipment, it’s critical to choose a reputable bead blaster manufacturer that aligns with your requirements. We recommend comparing at least four manufacturers using our comprehensive bead blaster directory, which allows you to:

- Review detailed business profiles highlighting each manufacturer’s experience, industry focus, and equipment capabilities.

- Use a direct contact form to request additional information or a custom quote tailored to your application.

- Preview each manufacturer’s website via our proprietary previewer tool, helping you quickly assess specializations and value propositions.

- Submit a single RFQ (Request for Quote) form to multiple manufacturers—streamlining your buying process and ensuring competitive pricing.

- Access verified customer testimonials and case studies to evaluate supplier reliability and after-sales service.

When evaluating manufacturers, consider asking:

- Does the manufacturer offer custom bead blaster configurations, or only standard models?

- What is their lead time and availability of replacement parts?

- Can they provide references or examples of successful installations in your industry?

- Do they offer operator training, on-site setup, and ongoing technical support?

- Is there a warranty or satisfaction guarantee on their bead blasting equipment?

For more guidance on selecting the best bead blaster manufacturer for your needs, visit our Bead Blaster Directory or request quotes from top-rated suppliers.

Frequently Asked Questions About Bead Blasters

- What safety precautions should I take when using a bead blaster?

Always wear appropriate personal protective equipment (PPE), including safety goggles, gloves, and respiratory protection. Operate bead blasters in well-ventilated areas or use enclosed blast cabinets with dust extraction to minimize exposure to airborne particulates. - What maintenance is required for bead blasting equipment?

Regular inspection of hoses, nozzles, seals, and media hoppers helps prevent leaks and optimize performance. Periodically clean or replace worn blasting media to maintain consistent results. Consult your manufacturer's manual for specific maintenance intervals. - How does bead blasting compare to sandblasting?

Bead blasting uses rounded beads, resulting in smoother, less aggressive finishes compared to sandblasting, which relies on angular sand particles for heavy material removal. Bead blasting is preferred for finishing, polishing, and delicate cleaning tasks. - Can bead blasters handle both small and large parts?

Yes, with the right equipment configuration, bead blasters can process everything from precision components to large industrial assemblies. Cabinet systems are best for small parts, while blast rooms accommodate larger items. - Where can I buy replacement bead blasting media and spare parts?

Leading bead blaster suppliers offer a full range of media types and sizes, as well as replacement parts and accessories for most equipment brands.

Still have questions about bead blasters or media selection? Ask a bead blasting specialist today for expert advice!

Deburring Machinery

Deburring Machinery Industrial Parts Washers

Industrial Parts Washers Sandblast Equipment

Sandblast Equipment Ultrasonic Cleaners

Ultrasonic Cleaners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services