MetFin

MetFinRequest A Quote

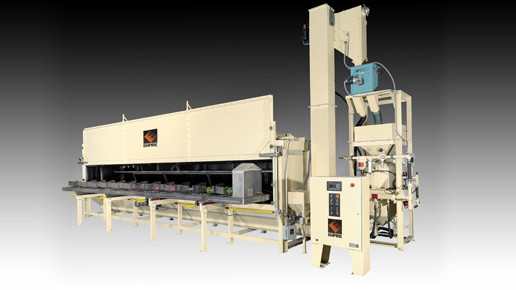

Suffield, CTMetFin is a leading provider of sandblast equipment products and services, offering innovative solutions to meet the diverse needs of industrial surface preparation. With a rich history spanning over two decades, MetFin has established itself as a trusted name in the industry, delivering high-quality equipment and exceptional customer service. Our sandblast equipment product line is designed to cater to various industries, including automotive, aerospace, manufacturing, and construction. We understand the critical importance of surface preparation in achieving optimal results, whether it's for cleaning, deburring, descaling, or preparing surfaces for coatings or adhesives. Our equipment is meticulously engineered to deliver consistent, efficient, and reliable performance, ensuring that our customers achieve the desired surface finish with precision. At MetFin, we offer a wide range of sandblast equipment options to suit different application requirements. We design solutions for rotary barrels, tube ID peening, blast room,s mesh belt systems, rotary barrels, spinner hangers, and automated ingot loaders. One of our core strengths lies in our commitment to customer satisfaction. We prioritize understanding the unique needs of each client and work closely with them to deliver tailored solutions. Our team of experienced engineers and technicians possesses in-depth knowledge of surface preparation processes, allowing us to provide expert guidance and support at every stage of the equipment selection, installation, and maintenance. MetFin's service capabilities extend beyond equipment supply. We offer comprehensive training programs to ensure that our customers are proficient in operating and maintaining our sandblast equipment. Our training sessions cover safety protocols, equipment operation techniques, troubleshooting, and maintenance procedures. We believe that empowering our customers with the necessary knowledge and skills is crucial for achieving optimal results and ensuring long-term equipment performance. Additionally, our after-sales service is second to none. Our dedicated support team is readily available to assist customers with any queries, technical issues, or spare parts requirements. We understand the importance of minimizing downtime in industrial operations, and we strive to provide prompt and efficient assistance to keep our customers' sandblast equipment running smoothly. MetFin is a trusted industry leader in sandblast equipment, offering a comprehensive range of products and services. We combine cutting-edge technology, industry expertise, and a customer-centric approach to deliver superior solutions for surface preparation needs. With MetFin as a partner, customers can rely on high-quality equipment, expert guidance, and exceptional support to achieve the best possible surface finish in their operations.

Deburring Machinery

Deburring Machinery Industrial Parts Washers

Industrial Parts Washers Sandblast Equipment

Sandblast Equipment Ultrasonic Cleaners

Ultrasonic Cleaners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services