Marco

MarcoRequest A Quote

Davenport, IAMarco is a leading provider of high-quality sandblast equipment and comprehensive service capabilities. With a rich history spanning over three decades, we have established ourselves as a trusted name in the industry, delivering innovative solutions to meet the diverse needs of our customers.

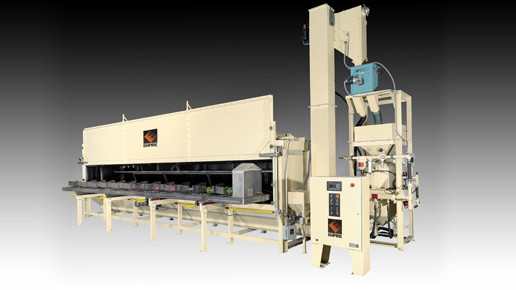

Our sandblast cabinets are available in various sizes and configurations, catering to different applications and workspaces. Whether you need a compact benchtop unit for small-scale projects or a large industrial cabinet for heavy-duty operations, we have the right solution for you. Our cabinets are designed to provide optimal visibility, ergonomic comfort, and effective containment of abrasive media, ensuring a clean and efficient blasting process.

At Marco, we prioritize customer satisfaction and strive to exceed expectations in every interaction. We have built strong relationships with a wide range of industries, including automotive, aerospace, manufacturing, construction, and more. Our commitment to quality, reliability, and customer-centricity has made us a preferred partner for sandblast equipment and services.

Marco is a leading provider of sandblast equipment, offering a comprehensive range of products and services to meet the diverse needs of our customers. With our cutting-edge solutions, industry expertise, and commitment to customer satisfaction, we are your trusted partner for all your sandblasting requirements.

Deburring Machinery

Deburring Machinery Industrial Parts Washers

Industrial Parts Washers Sandblast Equipment

Sandblast Equipment Ultrasonic Cleaners

Ultrasonic Cleaners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services