Flame Spray Technologies

Flame Spray TechnologiesRequest A Quote

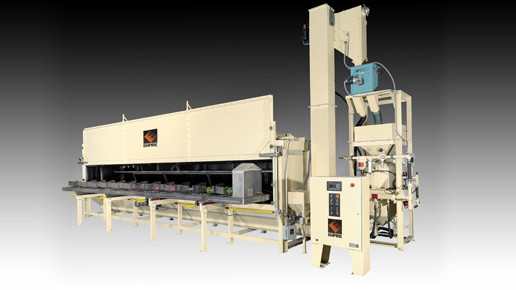

Grand Rapids, MI | 616-988-2622Flame Spray Technologies is a leading provider of innovative surface engineering solutions, specializing in sandblast equipment and related services. With a commitment to excellence and customer satisfaction, we have established ourselves as a trusted name in the industry. At Flame Spray Technologies, we offer a comprehensive range of thermal spray systems, auxiliary equipment, and turn-key systems. Our products include arc wire spray systems, flame powder spray systems, cold gas spray systems, plasma thermal spray systems, and flame wire spray systems. Our equipment is meticulously engineered to provide consistent and precise results. It is suitable for a wide range of applications, including cleaning, roughening, texturing, and etching surfaces of various materials. Our equipment can handle different abrasives such as silica sand, garnet, aluminum oxide, and more, offering flexibility in achieving the desired surface finish. Flame Spray Technologies is a trusted provider of thermal spray technologies and surface engineering solutions. With our superior quality equipment and comprehensive range of services, we empower our customers to achieve exceptional surface finishes while optimizing productivity and efficiency. Whether you need sandblast equipment for small-scale projects or large industrial applications, we are your reliable partner for all your surface preparation needs. Contact us today to explore how Flame Spray Technologies can assist you in achieving your surface engineering goals.

Deburring Machinery

Deburring Machinery Industrial Parts Washers

Industrial Parts Washers Sandblast Equipment

Sandblast Equipment Ultrasonic Cleaners

Ultrasonic Cleaners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services