Composition Materials Co., Inc.

Composition Materials Co., Inc.Request A Quote

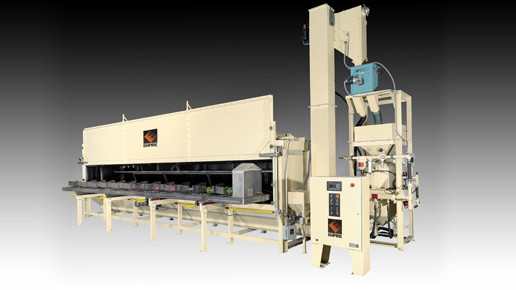

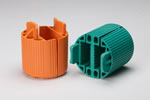

Milford, CT | 800-262-7763Composition Materials Co., Inc. is a renowned provider of sandblasting media. The company has established itself as a trusted industry leader in the field of surface preparation solutions. With a commitment to innovation, quality, and customer satisfaction, Composition Materials Co., Inc. has become a preferred choice for professionals seeking high-performance sandblast equipment. At Composition Materials Co., Inc., we understand the critical role that effective surface preparation plays in achieving superior results across various industries. Our sandblast equipment is designed to meet the demanding requirements of customers in industries such as aerospace, automotive, marine, construction, and manufacturing. Our products include plastic abrasives, organic abrasives, defleshing media, aluminum oxide, glass beads, steel shot, steel grit, silicon carbide, walnut shell blasting media, and more. One of our core product offerings is abrasive blasting media. We offer a wide selection of abrasive materials, including aluminum oxide, glass beads, steel grit, and plastic media. These abrasives are carefully selected and manufactured to deliver consistent results, ensuring optimal surface preparation for various applications. Our experienced team can assist you in choosing the right abrasive media for your project, taking into account factors such as material compatibility, desired finish, and environmental considerations. In addition to abrasive blasting media, we provide a diverse range of sandblast equipment and accessories. Our product lineup includes blast cabinets, blast rooms, portable sandblasters, blast pots, nozzles, hoses, and safety equipment. Whether you require small-scale equipment for occasional projects or large-scale systems for continuous operations, we offer versatile solutions that cater to your specific requirements. Beyond our product offerings, we also offer a range of value-added services. Our in-house engineering team can design custom sandblast equipment tailored to your unique specifications, enabling you to optimize efficiency and productivity in your operations. We provide equipment installation, training, and maintenance services to ensure that your sandblast equipment performs at its best over time. Additionally, our fast and reliable shipping services ensure that you receive your equipment and supplies promptly, minimizing downtime and keeping your projects on schedule. Composition Materials Co., Inc. is a leading provider of sandblast equipment, offering a comprehensive range of products and services to meet the diverse needs of professionals in various industries. With a legacy of excellence spanning nearly a century, we are dedicated to delivering superior surface preparation solutions, exceptional customer support, and innovative technology. Trust us to be your reliable partner in achieving exceptional results through sandblasting.

Deburring Machinery

Deburring Machinery Industrial Parts Washers

Industrial Parts Washers Sandblast Equipment

Sandblast Equipment Ultrasonic Cleaners

Ultrasonic Cleaners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services