Blast Cleaning Technologies

Blast Cleaning TechnologiesRequest A Quote

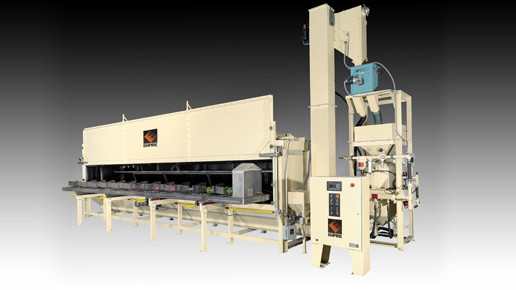

West Allis, WI | 262-785-7577Blast Cleaning Technologies specializes in the manufacturing of high-quality sandblasting equipment. Our extensive product lineup is designed to cater specifically to the needs of industries that rely on efficient and effective surface preparation and cleaning processes. Within our sandblasting equipment range, we offer a variety of cutting-edge solutions to suit different applications. Our drum blast systems provide a robust and automated approach to surface preparation, ideal for larger-scale projects. For targeted and precise blasting, our shot blast equipment ensures accurate and controlled abrasive distribution. Our table blast equipment offers versatility and convenience, allowing for efficient cleaning of smaller parts or components. In addition to our standard sandblasting equipment offerings, we excel in designing custom machinery tailored to the unique requirements of our clients. Whether you need specialized enclosures, automated systems, or specific blasting techniques, our experienced team can create a customized solution that fits your needs. To ensure the longevity and optimal performance of your sandblasting equipment, we provide a range of services. Our expert technicians offer upgrades, repairs, and conversions for your existing equipment, allowing you to enhance productivity and extend the lifespan of your investment. With a commitment to quality and innovation, Blast Cleaning Technologies is dedicated to providing top-of-the-line sandblasting equipment and exceptional service to industries that rely on efficient surface preparation and cleaning processes.

Deburring Machinery

Deburring Machinery Industrial Parts Washers

Industrial Parts Washers Sandblast Equipment

Sandblast Equipment Ultrasonic Cleaners

Ultrasonic Cleaners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services