There are innumerable contexts in which the process of improving metal strength is useful. Some of those contexts are architecture and construction, aircraft repairs, automotive spring manufacturing, surface finishing and other manufacturing contexts. Read More…

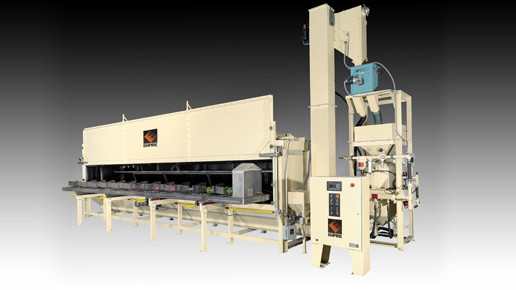

Our sandblast equipment is designed to handle a wide variety of applications and we use manufacturing methods that guarantee these machines will stand the test of time.

We have decades of experience in the finishing industry and we specialize in aqueous washing, abrasive blasting, vibratory finishing, polishing and buffing.

With over 100 years of combined dust-collecting experience, Rapid Prep LLC is a leader in the dust-collecting and sandblast equipment industry. We offer a wide range of products to meet the needs of our customers, with customization options available. Our team is dedicated to advancing our company and raising industry standards.

Cardinal Parts & Equipment LLC specializes in designing high-quality abrasive blasting equipment. The equipment they offer includes tumble blast equipment, rim blast equipment, dust collectors, and hanger blast equipment. They also sell abrasives like steel shot, stainless steel shot, and cast zinc shot. Their services include service calls, inspections, financing, and equipment rebuilding....

More Shot Peening Equipment Manufacturers

Peening is performed after products have already been manufactured and put to use. Descaling, decoring, sand removal and other structural improvements are often made to gear parts, clutch springs, camshafts, gearwheels, connecting rods, turbine blades and many other kinds of machinery through the process of shot peening.

Other processes that use non-metal peening media like glass or ceramics are still referred to as peening, though their applications are generally limited to softer surfaces that could be damaged by heavy, angular or bead-shaped blast media.

Peening as a metallurgical treatment dates back many years. It was originally performed with a peening hammer, the contact surface of which was usually curved. High-impact peening shot provides for the same effect but over a much wider area in much less time. Peening works by imparting residual compressive stress in a surface through the repeated collision of the surface and blunt instruments.

This stress translates, in terms of the properties the treated metal assumes after its treatment, into resistance to metal fatigue. Fatigue-resistant metals boast obvious advantages over untreated metal parts in applications where extended performance under demanding conditions is expected of the material. Aside from the potential for changing mechanical and performance properties of metals, shot peening can also be used as a cosmetic surface treatment.

Because the particulate size of steel shot and other metal shot materials is so large, it imparts much more visible impact artifacts than smaller media like silica or crushed walnut shells. Shot peening is often used to treat surfaces where an irregular decorative finish is desired. The way light is reflected by overlapping dimples caused by some varieties of shot peening treatment is one of the desirable features of shot peened surfaces.

Deburring Machinery

Deburring Machinery Industrial Parts Washers

Industrial Parts Washers Sandblast Equipment

Sandblast Equipment Ultrasonic Cleaners

Ultrasonic Cleaners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services