While a sandblaster can make use of any variety of blasting media and still be called a sandblaster, shot blasters make use of shot, which is a collection of small metal abrasives, exclusively. Read More…

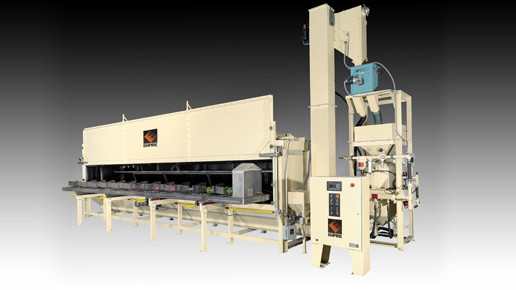

Our sandblast equipment is designed to handle a wide variety of applications and we use manufacturing methods that guarantee these machines will stand the test of time.

We have decades of experience in the finishing industry and we specialize in aqueous washing, abrasive blasting, vibratory finishing, polishing and buffing.

With over 100 years of combined dust-collecting experience, Rapid Prep LLC is a leader in the dust-collecting and sandblast equipment industry. We offer a wide range of products to meet the needs of our customers, with customization options available. Our team is dedicated to advancing our company and raising industry standards.

Cardinal Parts & Equipment LLC specializes in designing high-quality abrasive blasting equipment. The equipment they offer includes tumble blast equipment, rim blast equipment, dust collectors, and hanger blast equipment. They also sell abrasives like steel shot, stainless steel shot, and cast zinc shot. Their services include service calls, inspections, financing, and equipment rebuilding....

More Shot Blaster Manufacturers

The term "sandblaster" can be used in reference to all kinds of media blasting equipment. "Shot blasting" refers specifically to the use of shards or beads. Sandblasting can range in its applications from glass etching to glass snowing and from shot peening to soda blasting. Shot blasting would not be an appropriate glass treatment method, as the process involves propelling small shards, beads or other metal shapes at surfaces with a stream of compressed air or pressurized water.

Depending on the application, shot blasting professionals may choose media as fine and granulated as silicon carbide or as large as steel pellets. In both cases, but on different scales, the goal of shot blasting is the treatment of a surface. In the case of road treatment, for example, a portable, mobile shot blaster fires small steel beads at concrete surfaces to remove contamination and soft concrete.

This reveals a mechanical profile which allows for improved bonding during later resurfacing. The used shot and dust created by this process are usually collected by shot blaster, leaving a clean surface that is ready for treatment./p>

All media blasters, regardless of the kind of media they utilize, follow a few basic principles in terms of their design and function. Since all media blasters are intended to change a surface by propelling small objects, all media blasters must be equipped with a stock of blasting media, an air compressor or water pressurizer and a system by which those two components are combined and directed at surfaces.

There are three main configurations of media blasters in existence. Gravity-based systems are the simplest configuration and are mostly used in small scale blasting projects. In these systems, a hopper placed above the flow of compressed air uses gravity to combine the blasting media and airflow. In a siphon gun, the pressurized air passes over an unpressurized abrasive chamber.

The change in pressure draws abrasive up out of the chamber and into the flow of air, both of which are expelled through the nozzle at high speed. The third variety of media blaster is the pressure pot variety, which pressurizes both the air and the abrasive, allowing for an efficient flow of both.

Deburring Machinery

Deburring Machinery Industrial Parts Washers

Industrial Parts Washers Sandblast Equipment

Sandblast Equipment Ultrasonic Cleaners

Ultrasonic Cleaners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services